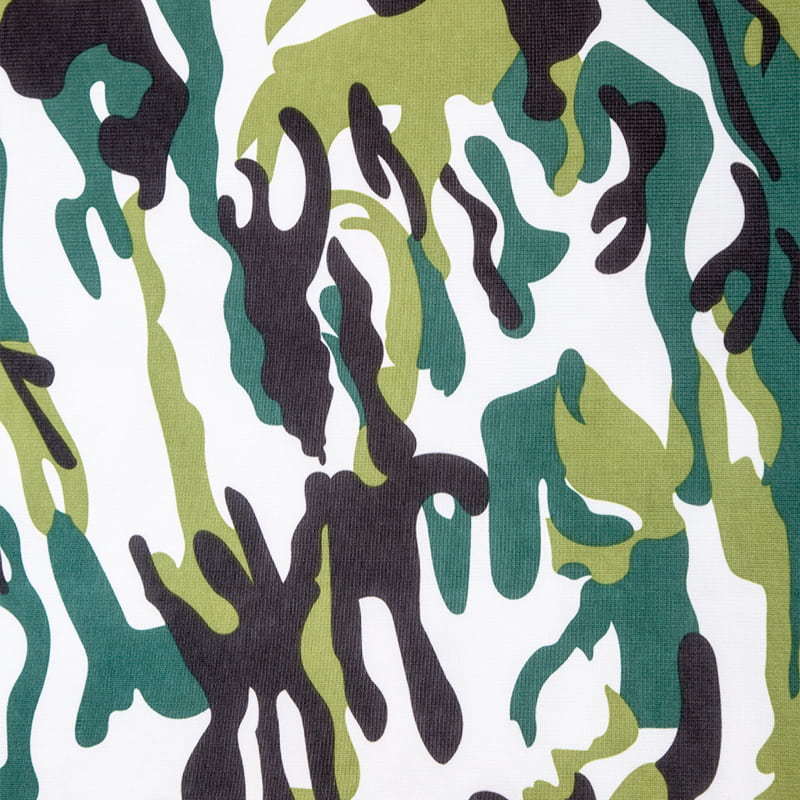

How The Printing Of Printed Super Poly Fabric Is Made

Printed super poly fabric is made by a process called sublimation printing. This process involves using heat and pressure to transfer dye onto the fabric, creating a permanent and vibrant coloration.

Here are the steps involved in sublimation printing of super poly fabric:

1. Design creation: The first step is to create the design that will be printed on the fabric. This can be done using computer software or by hand.

2. Printing: The design is then printed onto special transfer paper using sublimation inks that are designed to turn into gas when heated. The inks are printed in reverse, so that they will appear correctly on the fabric.

3. Fabric preparation: The super poly fabric is pre-treated with a special coating that helps the dye to adhere properly. The fabric is also cut to the desired size and shape.

4. Heat press: The printed transfer paper is placed face-down on the fabric and both are sandwiched between heated rollers of a heat press machine. The heat and pressure cause the ink to turn into gas, which penetrates the fibers of the fabric, bonding with them.

5. Cooling: The fabric is then allowed to cool, which solidifies the dye and makes it permanent.

6. Finishing: Finally, the printed fabric is inspected, trimmed, and prepared for use in various applications such as clothing, home decor, or accessories.

What Is The Function Of Printed Super Poly Fabric?

Super poly fabric is a type of synthetic fabric that is known for its durability, water resistance, and wrinkle resistance. Printed super poly fabric is a variety of this fabric that has been printed with designs or patterns using various printing techniques.

The function of

printed super poly fabric depends on the specific use case, as it can be used for a variety of purposes. Some common applications of printed super poly fabric include:

1. Clothing: Printed super poly fabric is often used to make lightweight and breathable clothing, such as shirts, dresses, and skirts. The fabric's water resistance and wrinkle resistance make it ideal for travel and outdoor activities.

2. Bags and backpacks: The durability and water resistance of printed super poly fabric make it a popular choice for bags and backpacks, especially those used for outdoor activities or travel.

3. Upholstery: Printed super poly fabric can be used for upholstery, such as on outdoor furniture, thanks to its water resistance and durability.

4. Flags and banners: The lightweight and weather-resistant properties of printed super poly fabric make it a popular choice for outdoor flags and banners.

Production Standards For Printed Super Poly Fabrics

Super Poly Fabrics are high-performance fabrics that are popularly used in a range of applications, including outdoor gear, sports apparel, and flags. These fabrics are made from a combination of polyester and nylon, and are known for their durability, strength, and resistance to abrasion, chemicals, and UV radiation.

To produce

printed Super Poly Fabrics that meet the required standards, several production standards need to be followed. Here are some of the key standards that should be considered:

1. Fabric Selection: The selection of the base fabric is crucial to the final product's quality. The fabric should be of high quality, uniform in texture, and free from any defects or flaws that could impact the final print.

2. Printing Techniques: Different printing techniques can be used, such as dye sublimation, screen printing, or direct-to-fabric printing. The printing technique chosen will depend on the fabric type and the required design.

3. Ink Quality: High-quality inks should be used to ensure the final product is vibrant and durable. The inks should be able to withstand abrasion, fading, and washing.

4. Pre-treatment: Prior to printing, the fabric should be pre-treated to ensure that it is free from any contaminants that could interfere with the printing process.

5. Quality Control: Regular quality control checks should be carried out during the printing process to ensure that the final product meets the required standards. These checks should include monitoring color consistency, print quality, and fabric strength.

6. Environmental Standards: The production of

printed Super Poly Fabrics should comply with relevant environmental standards. The production process should minimize waste and pollution and ensure that any chemicals used are safely disposed of.

English

English Español

Español