In the modern textile industry, Warp Knitting Fabric is being favored by more and more companies and designers for its excellent performance and wide applicability. Compared with traditional weft knitting fabrics, warp knitting technology continues to expand its application in clothing, home furnishings, industry and even medical fields with the advantages of high speed, high stability and high efficiency.

What is warp knitting fabric? ——From the weaving principle

"Warp knitting" is a weaving method relative to "weft knitting". Warp knitting fabric is mainly based on warp yarn. The warp knitting machine is used to weave the yarn along the longitudinal direction of the cloth surface. Its most notable feature is that the fabric has good dimensional stability in both the longitudinal and transverse directions.

During the operation of the warp knitting machine, multiple warp yarns are supplied from the creel at the same time, and the yarns are wound around the warp knitting needles to form coils. The yarns are knitted in sequence through the swing of the needle bed to form an interlaced and orderly fabric structure. According to different weaving rules and needle types, a variety of patterns and tissue structures can be formed.

Common warp knitted fabric types include:

Single needle bed warp knitted fabric (such as strong weft tensile force and low elasticity)

Double needle bed warp knitted fabric (can form a three-dimensional structure, suitable for three-dimensional mesh, 3D spacer fabric, etc.)

Five core advantages of warp knitted fabric

1. Excellent stability and not easy to deform

Because the warp yarns are closely arranged and the longitudinal coils support each other, warp knitted fabrics have excellent dimensional stability and are particularly suitable for high-end sportswear, swimwear and other products that require the fabric to be not easy to deform.

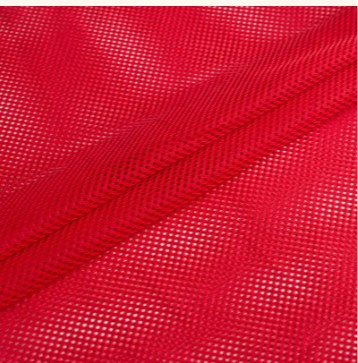

2. Strong breathability and good quick-drying properties

Most warp knitted fabrics use a mesh structure with uniform pores and good breathability. They can quickly wick away sweat and heat in high temperatures or intense exercise, keeping the wearer dry.

3. High-speed production and high efficiency

The warp knitting machine runs fast, can achieve large-scale and continuous production, and is suitable for commercial rapid delivery needs. It is an important reason why sports brands and outdoor brands favor it.

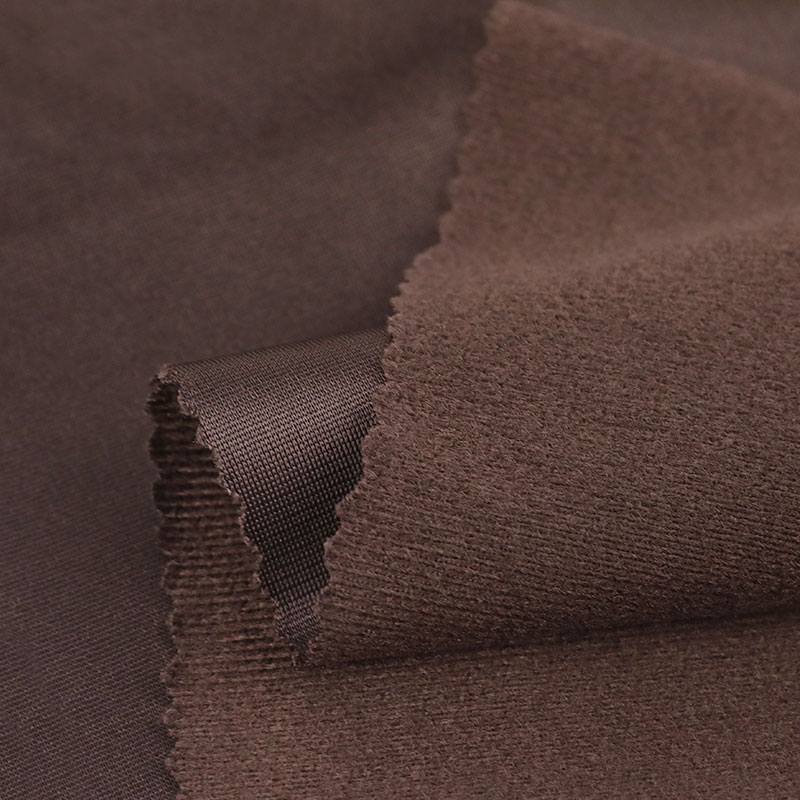

4. Diverse appearance and feel

By changing the weaving structure and yarn type, warp knitted fabrics can achieve different gloss, texture, elasticity and texture, from matte to high gloss, from soft to crisp, all can be customized, with great design space.

5. Strong functionality, can be integrated with a variety of special fibers

In practical applications, warp knitted fabrics are often compounded with Coolmax, Lycra, Spandex, flame retardant fibers, antibacterial fibers, etc., giving the fabrics multiple functions such as UV resistance, antibacterial and deodorization, and long-lasting elasticity.

What are the main application areas of warp knitted fabrics?

1. Sports and outdoor functional clothing

Due to its high elasticity, quick drying and durability, warp knitted fabrics are the preferred material for professional sportswear (such as running clothes, cycling clothes, yoga clothes, swimwear, etc.). In particular, double-sided elastic mesh fabrics and elastic warp knitted fabrics are widely used in this field.

2. Medical and health industry

Warp knitted fabrics have good air permeability and stability, so they are often used in medical bandages, surgical gowns, and mask inner materials, especially polyester warp knitted nonwovens, which can improve fit and comfort.

3. Industry and automotive interiors

In the industrial field, warp knitted fabrics are often used as filter materials, composite base fabrics, car seat fabrics, etc. Their high strength and excellent dimensional retention can meet long-term durability requirements.

4. Home and decorative products

High-end home textile products such as curtain fabrics, sofa fabrics, and bedspreads are also gradually using warp knitted fabrics, especially 3D three-dimensional spacer mesh fabrics, which are not only beautiful and breathable, but also suitable for use in all seasons.

How to choose between warp knitted fabrics and weft knitted fabrics? ——Performance comparison at a glance

| Comparison dimension | Warp knitted fabrics | Weft knitted fabrics |

| Weaving method | Multiple warp yarns are woven longitudinally at the same time | Single yarn wrapped horizontally |

| Elastic performance | Good transverse elasticity, weak longitudinal elasticity | Good horizontal and vertical elasticity |

| stability | High, the structure is not easy to deform | Slightly worse, easy to pill or curl |

| Breathability | Excellent, loose structure | Generally, the air permeability decreases when the density is higher. |

| Application Areas | Sports, medical, industry and other industries with high functional requirements | Underwear, sweaters and other comfortable clothing |

As a high-performance and highly adaptable fabric form, warp knitted fabrics are reshaping people's perception of "knitting". It not only meets the efficiency requirements of large-scale industrial production, but also realizes the expansion of high-level functions through structural innovation and material integration. Whether you are a brand owner, designer, or a purchaser of surface and auxiliary materials, warp knitted fabrics are a category worthy of special attention.

English

English Español

Español