In the modern textile industry, Warp Knitting Fabric, with its unique structure and superior performance, has become a key choice for various high-end apparel, home furnishings, and industrial applications. With continuous technological advancements, warp-knitted fabrics not only excel in appearance and feel but also demonstrate significant advantages in functionality and durability.

Structural Advantages and Process Characteristics of Warp Knitting Fabric

The most distinctive feature of Warp Knitting Fabric lies in the continuity of its warp yarns. This unique structure ensures the stability and strength of the fabric. Compared to weft-knitted fabrics, warp-knitted fabrics exhibit superior longitudinal tensile strength and shape retention, making them widely used in apparel and functional fabrics.

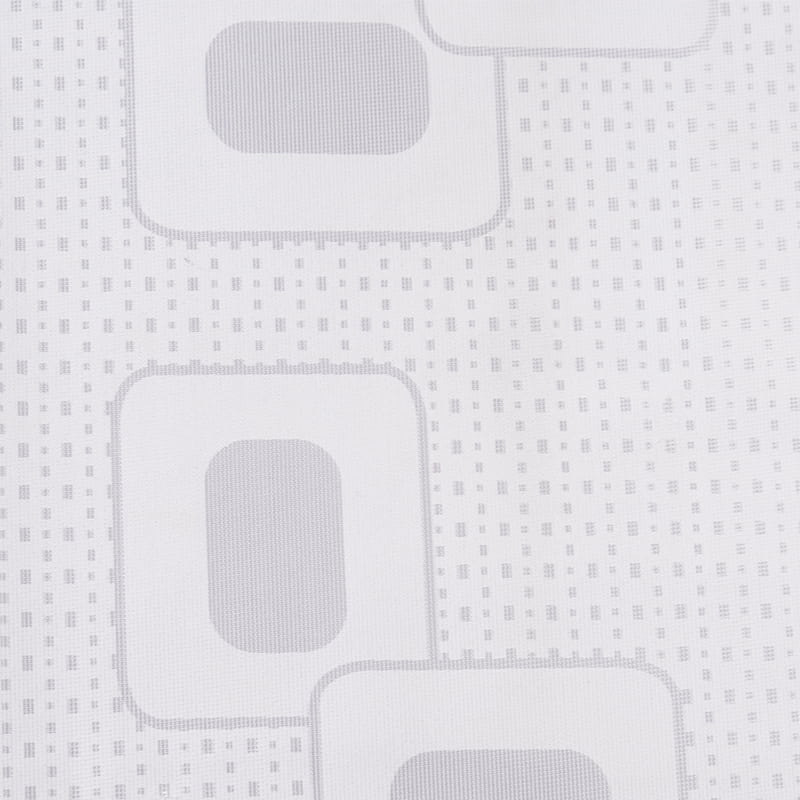

Modern warp knitting technology utilizes advanced computer-controlled equipment to achieve precise weaving of complex patterns and functional structures. This not only enhances the aesthetics of the fabric but also provides more possibilities for functional materials. For example, by changing the type and density of yarns, fabrics can be endowed with various properties such as waterproofing, breathability, antibacterial properties, or elasticity. The manufacturing process of Warp Knitting Fabric ensures both high efficiency and consistent, high-quality products, which is especially crucial for export trade.

Superior Durability and Performance

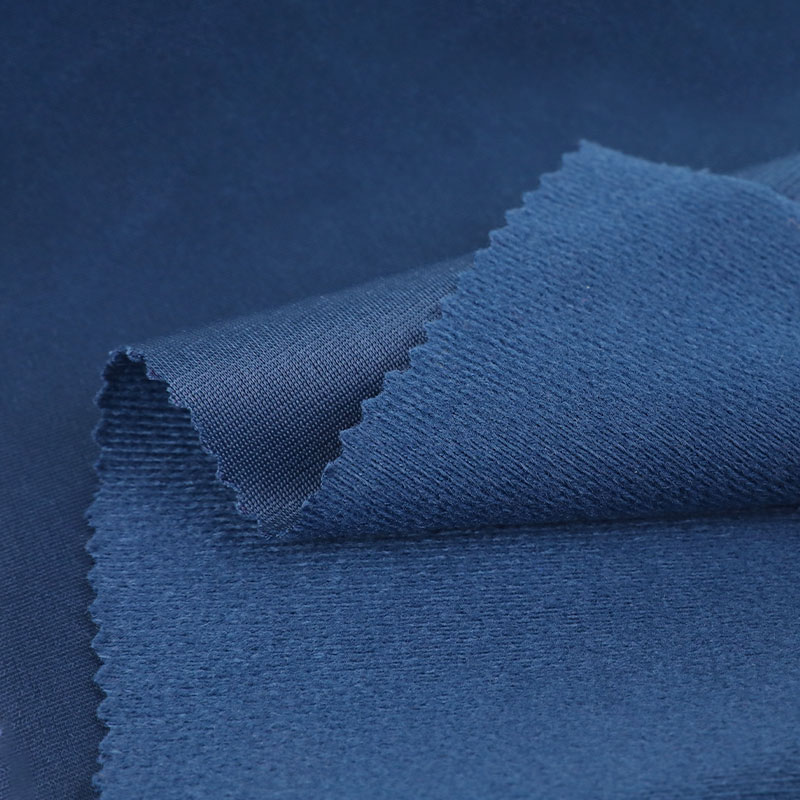

Warp Knitting Fabric boasts significant advantages in durability. Its continuous warp yarn arrangement allows for even stress distribution under load, greatly reducing the risk of breakage and deformation. This characteristic makes warp-knitted fabrics stand out in industrial fabrics, automotive interiors, and high-end sportswear, meeting the demands of long-term use and harsh environments.

The breathability and moisture absorption of warp-knitted fabrics can be flexibly adjusted according to the yarn structure, providing excellent comfort and health performance in functional clothing and medical materials. The wrinkle resistance, tensile strength, and shape retention of Warp Knitting Fabric also offer international buyers a high-value-added option.

Diverse Applications Drive Market Demand

Warp Knitting Fabric not only holds a significant position in the apparel industry but is also widely used in home décor, sporting goods, automotive interiors, and industrial filtration materials. Its flexible structure and adjustable performance allow the fabric to meet the specialized needs of various application scenarios. In the high-end apparel sector, Warp Knitting Fabric is favored for its lightweight, elasticity, and soft hand feel, enabling the creation of comfortable and stylish garments. In the industrial sector, its high strength and abrasion resistance make it a key component in protective equipment, filtration materials, and technical textiles. This wide range of applications not only demonstrates the versatility of Warp Knitting Fabric but also creates stable market demand for export companies.

Green and Sustainable Development Advantages

With increasing global environmental awareness, Warp Knitting Fabric demonstrates strong potential for sustainable development in its production and application. Advanced warp knitting technology enables efficient yarn utilization and reduces waste, while the use of renewable or environmentally friendly fibers reduces environmental burden.

In export trade, environmental certifications and sustainable materials have become important procurement standards for international customers. The green characteristics of Warp Knitting Fabric not only meet these requirements but also establish a positive image and competitive advantage for companies in the international market. This product advantage, which balances performance and environmental friendliness, further solidifies its position in the future textile market.

Technological Innovation Drives Future Development

The development of Warp Knitting Fabric is inseparable from the driving force of technological innovation. With the widespread adoption of automated knitting equipment and intelligent control technologies, fabric design and production efficiency are continuously improving. The application of high-performance yarns, composite materials, and functional coatings enables warp-knitted fabrics to achieve more functions, meeting increasingly diverse market demands.

International buyers are increasingly focusing on the functionality, customizability, and high added value of warp knitting fabrics. The application of advanced technologies not only enhances product competitiveness but also brings broader market opportunities to exporting companies. In the future textile market, warp-knitted fabrics will continue to meet high-end demands through innovation, becoming an important growth point in global trade.

Warp knitting fabric, with its unique structure, superior durability, diverse applications, and environmental advantages, has become an indispensable high-performance material in the textile industry. In international trade, this fabric not only meets the professional needs of multiple fields but also provides companies with significant market competitiveness. With continuous technological advancements and the promotion of green development, the application prospects of warp knitting fabric will be even broader, injecting continuous innovation momentum into the global textile market.

English

English Español

Español