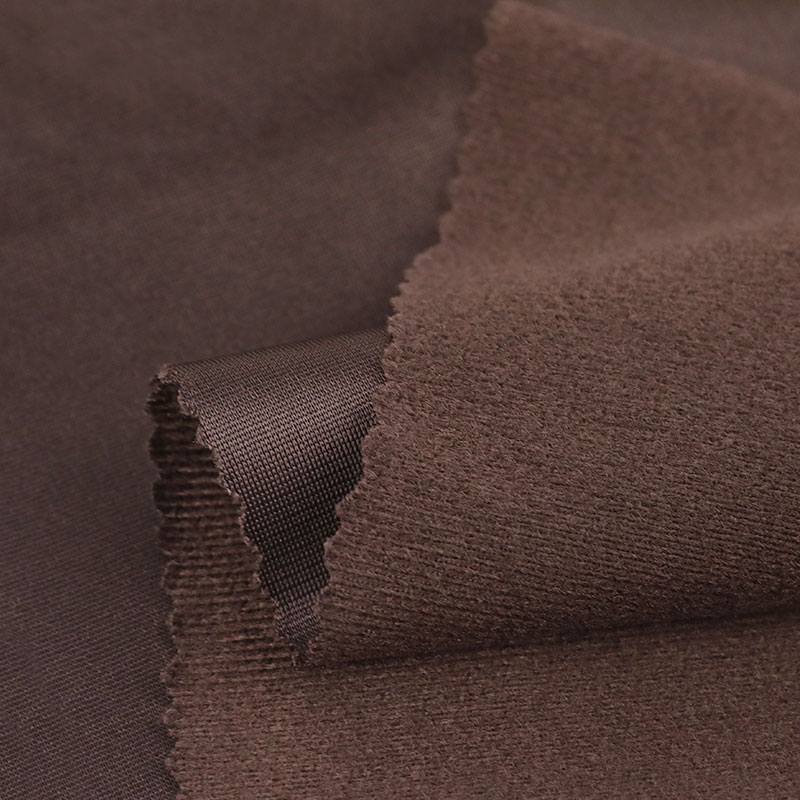

Warp-knitted fabrics have a lower vertical stretch than weft-knitted fabrics, but they are known for their high crosswise stretch. As a result, warp-knitted fabric can be used to produce highly elastic and form-fitting garments. Warp-knitted fabric is also very abrasion-resistant and durable and does not ravel or delaminate.

As with woven fabric, there are many different types of warp-knitted fabrics available. Some of the more common include mirror satin, powernet and satinet. These fabrics are commonly found in intimate apparel, shape wear and swimwear, as they provide a smooth and shiny surface on the technical back of the fabric that provides comfort to the skin. Other common forms of warp-knitted fabric are tricot, velour and jacquard.

The basic pattern of warp knitting is where parallel yarns zigzag lengthwise along the fabric with each loop securing the loop of an adjacent yarn in the same course. The length of the underlap in a course determines how tightly knitted the fabric is and how much it will stretch longitudinally. In general, longer underlaps produce more elasticity and a tighter knit; shorter underlaps allow the fabric to have a lighter feel.

There are several types of knitting patterns that can be used to create different types of warp-knitted fabric. The atlas mesh pattern, for example, produces a mesh fabric that can be either open or closed. A more advanced mesh pattern, the twill mesh, has the same appearance but is less abrasion resistant and less stretchy than the atlas mesh fabric.

Other pattern types are being investigated for the production of mesh reflector surfaces. The requirements for a mesh reflector surface include that the mesh should be as closed structured as possible, while having a sufficient drapability to maintain its parabolic shape. In addition, the mesh should have a good air permeability.

The requirements for the mesh reflector fabric are being determined by optical analysis and by evaluating different patterns on a warp-knitting machine. The two main types of warp-knitting machines are raschel and tricot machines. Raschel machines have multiple sinkers that function as the main control of the fabric during the loop formation. In contrast, tricot machines use only a few sinkers. These machines can be modified to produce a wider range of different patterns by changing the take-up direction of the warp threads, number of guide bars and machine speed.

English

English Español

Español