Among the myriad fabric categories in the textile industry, warp knitting fabric is gradually gaining market attention due to its unique properties and wide applicability. This fabric, woven primarily in the warp direction, not only offers significant advantages in production efficiency but also boasts structural stability and functional versatility, making it a preferred material for a wide range of applications, including apparel, home textiles, and industrial textiles.

The Structural Code of Warp Knitting Fabric: The Unique Logic of Warp and Weft Interweaving

Warp knitting fabric's core competitiveness stems from its unique weave structure. Unlike weft-knitted fabrics, which form loops by weaving a single yarn horizontally, warp-knitted fabrics consist of multiple warp yarns arranged parallel to each other longitudinally. The circular motion of the knitting needles creates an interlocking loop structure. This weaving method minimizes longitudinal stretch and enhances dimensional stability. Even after repeated stretching, the fabric quickly returns to its original shape, making it a popular choice for applications where shape retention is crucial.

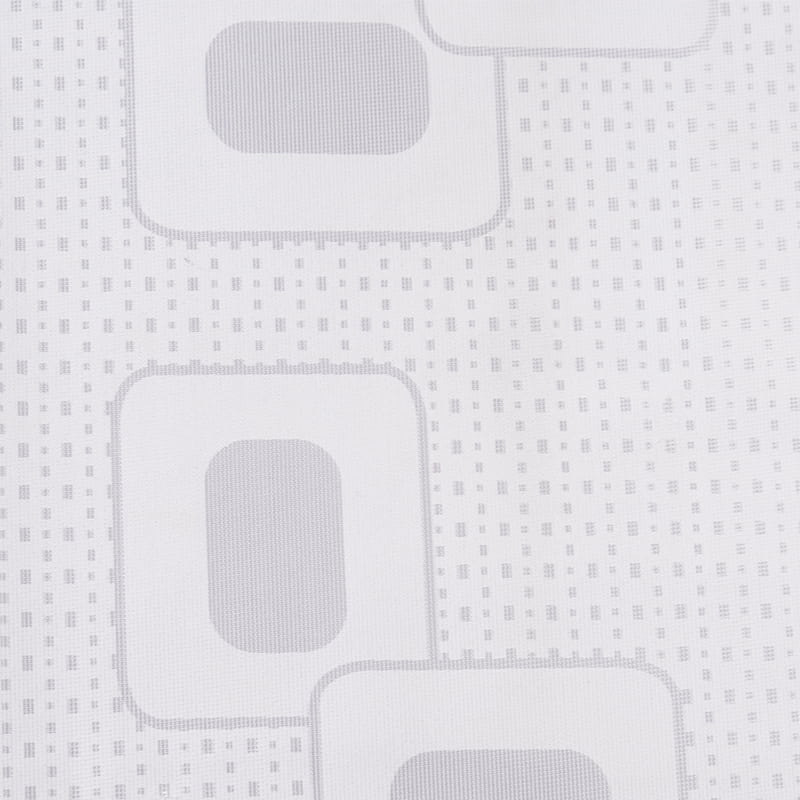

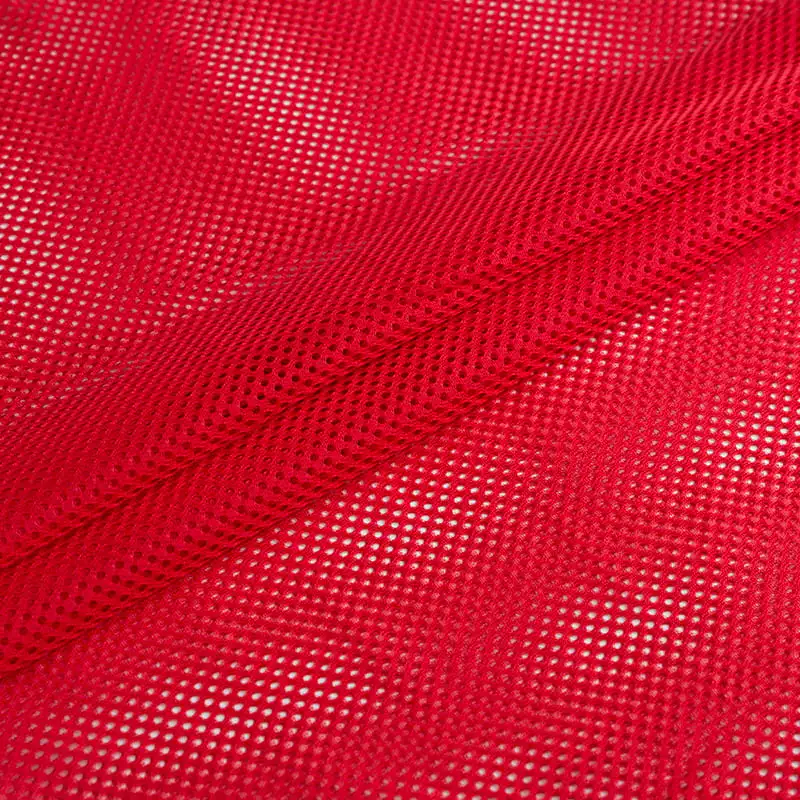

The fabric's surface texture is also a highlight of the warp knitting process. Because warp yarns can be combined with different threading methods and needle-bar motions during the weaving process, a wide variety of patterns can be formed, including plain, mesh, and jacquard. Warp knitted fabrics with mesh structures are often used in summer clothing and sportswear due to their excellent breathability. The complex patterns created by the jacquard technique allow fabrics to combine decorative and practical features, providing greater creative possibilities for high-end home textile and fashion design.

The loop density of warp knitting fabrics can be precisely controlled through process parameters, which directly affects the fabric's thickness, elasticity, and feel. High-density warp knitting fabrics are firm and suitable for warm clothing, while low-density fabrics are light and soft, making them widely used in children's clothing and underwear. This structural flexibility allows warp knitting fabrics to meet the personalized needs of different applications.

Technological Innovation: Driving the Performance Upgrade of Warp Knitting Fabrics

The quality improvement of warp knitting fabrics is inseparable from continuous innovation in production technology. Modern warp knitting machines have evolved from traditional mechanical control to electronic jacquard systems, which not only enable the weaving of more complex patterns but also significantly improve production efficiency and fabric consistency. At the same time, the application of new fiber materials has also brought more functional properties to warp knitting fabrics.

Diverse Application Scenarios: The Market Potential of Warp Knitting Fabric

The application areas of warp knitting fabric are continuously expanding, extending from traditional clothing and home textiles to industrial textiles. In the clothing sector, warp knitting fabrics, due to their excellent elasticity and shaping properties, have become the fabric of choice for tights, sportswear, swimwear, and other apparel. In the furniture and home textile sector, warp knitted sofa fabrics and curtain fabrics are popular among consumers for their rich colors, wear resistance, and durability.

Industrial textiles are one of the fastest-growing application areas for warp knitting fabrics. In the construction industry, warp knitted mesh fabrics, as a reinforcement material, can effectively improve the crack resistance of walls. In the automotive industry, warp knitting fabrics are used in car seats, interior components, and other components. They are not only aesthetically pleasing and comfortable, but also have excellent flame retardancy and wear resistance. In the agricultural sector, warp knitted sunshade nets and insect repellent nets provide a suitable environment for crop growth, promoting the development of modern agriculture.

As consumers' requirements for material performance increase, the market demand for warp knitted fabrics will continue to grow. In the future, warp knitted fabrics that are environmentally friendly, functional, and personalized will become the development trend of the textile industry, bringing more innovative possibilities to various application fields.

English

English Español

Español