In the wave of upgrading the global textile industry, Warp Knitting Fabric has gradually become a key link connecting basic textiles and high-end manufacturing with its unique production logic and excellent product performance. Compared with traditional fabrics, the advantages of warp knitted fabrics in structural stability and functional plasticity make it not only meet the needs of daily consumption, but also show irreplaceable value in high-end industrial scenarios.

The principle of warp knitted fabrics: the core logic from yarn loops to fabric molding

The core of the process of warp knitting fabric lies in the "warp-ring" weaving method, which is different from the transverse weaving of weft knitting fabric. It moves synchronously along the longitudinal direction of the fabric through multiple yarns to form a continuous and mutually connected coil structure. In the warp knitting production system, after the yarn is drawn out from the warp shaft, the warp guide needle is accurately controlled, and it works in concert with knitting needles, settler sheets and other components according to the preset knitting structure rules to complete the formation, transfer and connection of the coil. During the entire process, the tension control of the yarn, the movement trajectory of the yarn guide needle, and the lifting and falling frequency of the knitting needle jointly determine the structural density and performance of the fabric.

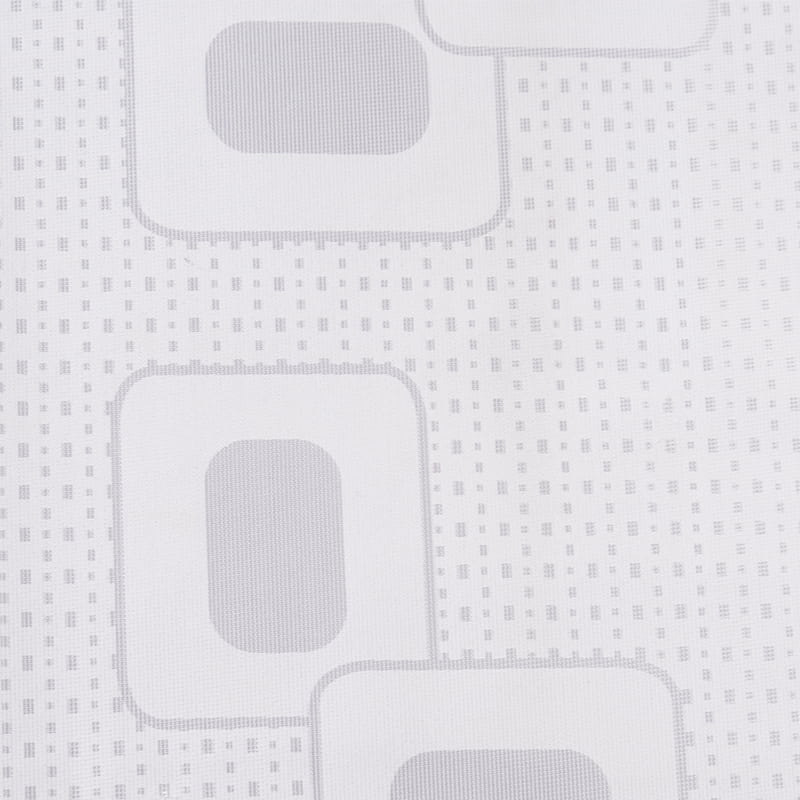

Modern warp knitting production processes are highly dependent on the level of precision and automation of equipment. The number of bars, knitting speed, needle bed specifications and other parameters of the warp knitting machine directly affect the production efficiency and product quality of the fabric. By optimizing the arrangement of the bar and the yarn configuration, warp knitting fabric production with different tissue structures can be realized, such as plain warp knitting, jacquard warp knitting, jacquard warp knitting, etc. Each tissue structure corresponds to different fabric characteristics, providing diversified choices for subsequent application scenarios. At the same time, the continuous production characteristics of the warp knitting process enable it to reduce material waste in the production process, improve resource utilization efficiency, and provide the possibility for large-scale standardized production.

The process flow of warp knitted fabrics also covers the pre-preparation and post-organization. In the preparatory stage, the yarn needs to be treated with winding, warping, etc. to ensure that the yarn tension is uniform and free of defects, laying the foundation for the subsequent weaving process; the rear finishing process is further optimized through washing, shaping, functional finishing and other processes, so that warp knitted fabrics can better meet the needs of downstream application fields.

Performance optimization of warp knitted fabrics: a systematic solution from material selection to process regulation

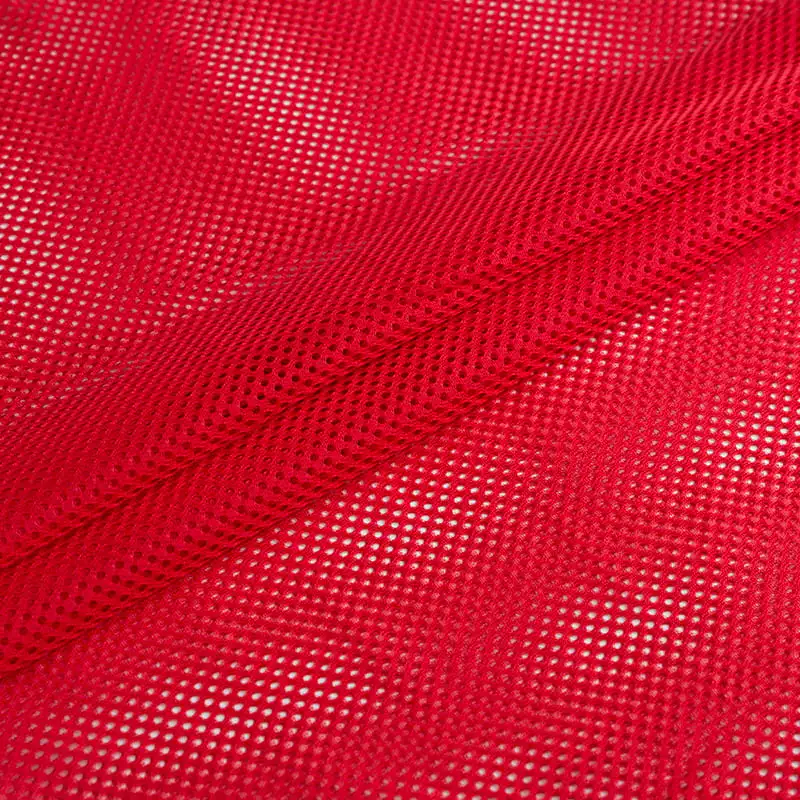

Material selection is the basic link in the performance optimization of warp knitted fabrics. Different types of yarn materials, such as natural fibers, chemical fibers, functional fibers, etc., give warp knitted fabrics different performance characteristics. Natural fibers such as cotton and wool can improve the skin-friendliness and breathability of warp knitted fabrics, and are suitable for use in close-fitting clothing and home textile products; chemical fibers such as polyester and nylon have high strength, wear resistance, easy care and other characteristics, and are suitable for industrial warp knitted fabrics and sports clothing; functional fibers such as antibacterial fibers, flame retardant fibers, moisture-absorbing and sweating fibers, etc. can give warp knitted fabrics specific functions and expand their application space in high-end fields.

Process regulation is a key means to optimize the performance of warp knitted fabrics. By adjusting the weaving parameters of the warp knitting machine, such as coil length, bar pad movement, weaving speed, etc., the structural density and elastic recovery of the fabric can be changed. Shortening of the coil length can improve the density and strength of the fabric, while increasing the coil length can improve the elasticity and breathability of the fabric; changes in the movement of the comb pad yarn can form different fabric textures and structures, affecting the feel and appearance of the fabric; reasonable control of the weaving speed can ensure production efficiency while reducing quality problems such as yarn breakage and coil dispersion, ensuring stable fabric performance.

Functional finishing technology provides additional support for performance optimization of warp knitted fabrics. By adopting coating, composite, nanotreatment and other technologies, functional coatings or structures can be formed on the surface of warp knitted fabrics, giving the fabric anti-fouling, waterproof, antibacterial, ultraviolet rays, flame retardant and other characteristics. For example, through the waterproof finishing process, a hydrophobic coating can be formed on the surface of the warp knitted fabric to prevent moisture from penetration and make the fabric suitable for outdoor clothing and protective products; through the antibacterial finishing process, bacterial growth on the surface of the fabric can be inhibited, and the hygiene and safety of the fabric can be improved. It is suitable for medical care and underwear products. The application of these functional finishing technologies makes the performance of warp knitted fabrics more diversified and can adapt to more complex usage environments.

Market demand adaptation of warp knitted fabrics: demand response from consumption upgrade to industrial transformation

Against the background of consumption upgrading, the demand for warp knitted fabrics in the daily consumption field shows a trend of high quality, personalization and functionalization. In the clothing market, consumers put forward higher requirements on the comfort, aesthetics and functionality of clothing. Warp knitted fabrics have become the preferred fabric for sportswear, fashionable underwear, and high-end casual clothing with their good elasticity, breathability and appearance plasticity. The home textile market focuses on the durability, environmental protection and decorativeness of fabrics. By optimizing materials and processes, warp knitted home textile fabrics integrate environmental protection concepts and fashionable design elements while ensuring product durability, to meet consumers' pursuit of high-quality home life.

The transformation and development of the industrial field brings new market demand for warp knitted fabrics. The automobile industry is developing towards lightweight, intelligent and green, and the requirements for lightweight, environmental protection and wear resistance of automobile interior fabrics have been improved. Warp knitted fabrics have become an important choice for automobile interior fabrics due to their high strength, lightweight, easy processing and other characteristics; the medical industry has strict requirements on the hygiene, safety and protective performance of medical textiles. Warp knitted medical fabrics can meet the needs of medical scenarios by using antibacterial materials and special processes; high-end industries such as new energy and aerospace have special requirements for the high temperature resistance, aging resistance, and high strength properties of warp knitted fabrics, which promote the development of warp knitted fabrics toward high performance and high value-added.

Changes in market demand have also promoted the warp knit fabric industry toward customization and differentiation. Downstream customers put forward personalized needs for the performance, specifications, appearance, etc. of warp knitting fabrics based on their own product characteristics and application scenarios, prompting warp knitting companies to quickly respond to market demand through flexible production technology and customized services. At the same time, enterprises develop differentiated products, such as warp knitted fabrics with unique textures and special functions, to form their own competitive advantages, avoid homogeneous competition, and occupy an advantageous position in the segmented market.

With the continuous development of the global textile industry and the continuous evolution of market demand, the warp knit fabric industry needs to continuously optimize process technology, improve product performance, and strengthen market demand adaptability to cope with increasingly fierce market competition. In the future, warp knitted fabrics will play an important role in more fields and provide strong support for the high-quality development of the textile industry.

English

English Español

Español