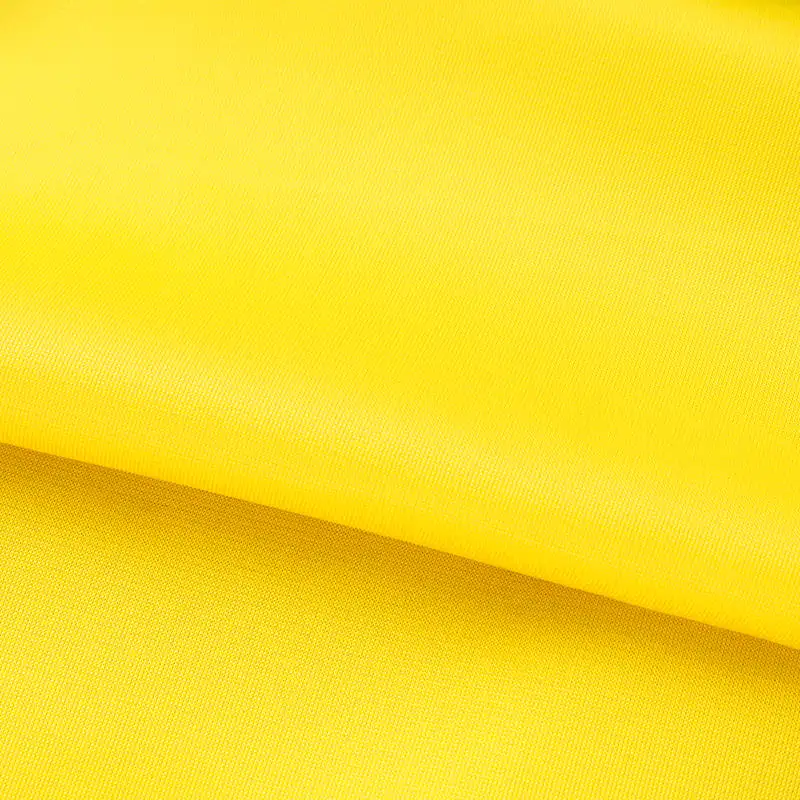

As a high-performance textile fabric, Tricot Fabric has gradually emerged in the market in recent years, especially in the fields of sportswear, underwear, home decoration and high-end fashion. Compared with traditional weft-knitted fabrics, Tricot Fabric has significant advantages in performance and use.

Basic definition and structure of Tricot Fabric

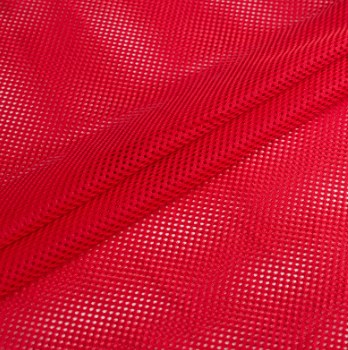

Tricot Fabric is a textile woven with longitudinal (warp) yarn as the main thread, and warp knitting machines are used in the production process. This fabric has a very tight structure, strong stretchability and resilience, and is usually made by weaving yarns along the warp direction. Compared with weft-knitted fabrics (usually woven horizontally), the yarns of warp knitted fabrics are more stable, have a long service life, and are not easy to deform.

The structure of Tricot Fabric includes single-sided and double-sided. Among them, double-sided warp knitted fabrics often have a more uniform fabric surface, which is suitable for high-demand clothing design and decorative purposes.

Unique advantages of Tricot Fabric

1. Strong stretch resistance and wear resistance

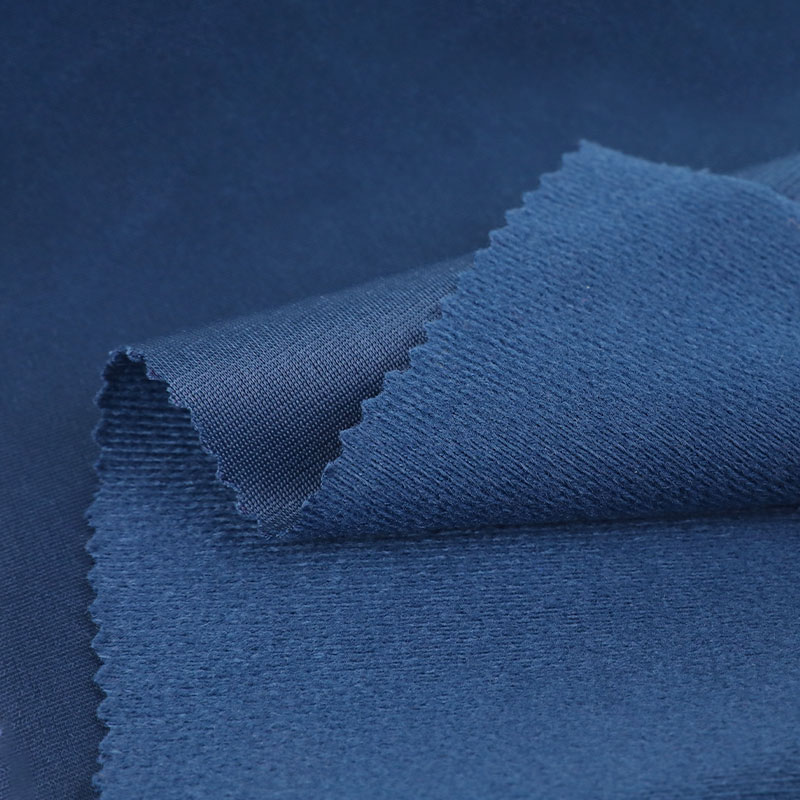

A prominent feature of Tricot Fabric is its excellent stretch resistance and wear resistance. This makes it widely used in sportswear, outdoor products, car seats and industrial fabrics. Compared with traditional fabrics, Tricot Fabric has higher strength and tensile resistance, and can maintain excellent performance in high-intensity use environments.

2. Elasticity and comfort

Due to the special weaving method of Tricot Fabric, it has good elasticity and comfort. For close-fitting clothing such as sportswear and underwear, the elasticity of the fabric not only provides enough space for movement, but also provides certain support to the body during exercise. The softness and adaptability of Tricot Fabric make it very suitable for making tights, sports pants, yoga clothes and other products.

3. Excellent breathability and moisture absorption

Tricot Fabric can improve its breathability and moisture absorption by changing the arrangement of yarns during the weaving process. Especially in the application of sportswear and underwear, the fabric can effectively absorb moisture and perspiration, keep the body dry, and improve the comfort of wearing.

Tricot Fabric Production Process

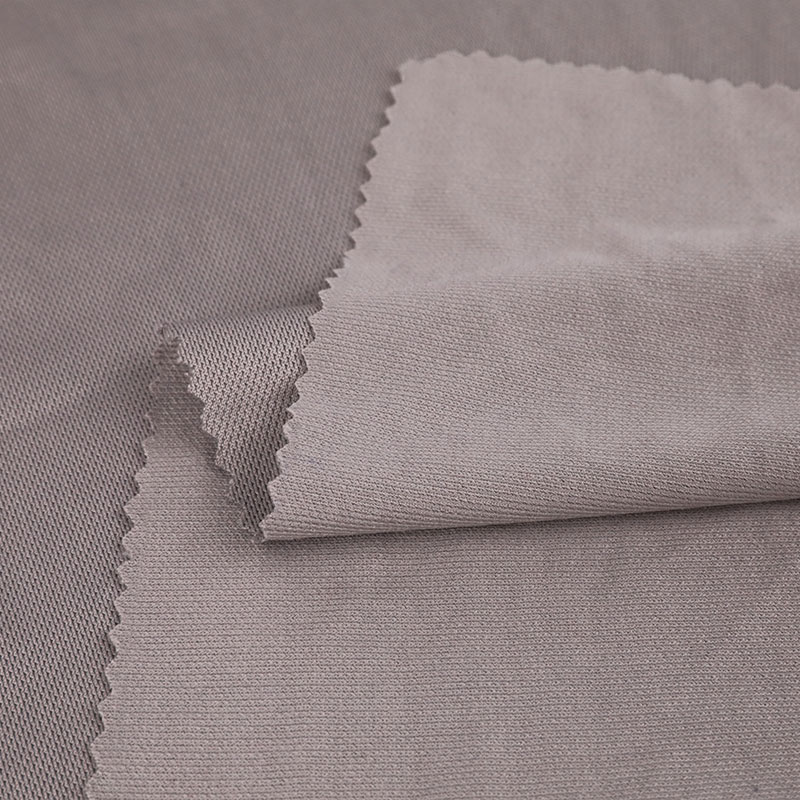

The production process of Tricot Fabric is more complicated than that of traditional weft knitting or woven fabrics, but its advantages also lie in this. The warp knitting machine weaves the yarn longitudinally and produces fabrics with different functions and effects under different needle counts, densities and yarn types. Common types of warp knitting machines include flat knitting machines, circular knitting machines, stretch knitting machines, etc.

In actual production, manufacturers will adjust the thickness, material, dyeing process, etc. of the yarn according to customer needs to meet the various needs of Tricot Fabric on the market. According to the material of the yarn, common Tricot Fabrics include nylon, polyester, spandex, wool, etc. The choice of these different materials determines the final application range of warp knitted fabrics.

Wide application of Tricot Fabric

1. Sports and leisure wear

With the changes in people's lifestyles, the demand for sports and leisure wear is increasing, and warp knitted fabrics are widely used in this field. Its excellent elasticity and comfort make it an ideal material for making sportswear such as sports bras, yoga clothes, and running clothes.

2. Underwear and intimate wear

Due to its good elasticity, comfort and breathability, Tricot Fabric is often used to make underwear, base shirts and other intimate wear. During the production process, the softness of the fabric can minimize friction on the skin and provide a comfortable wearing experience.

3. Home Decoration and Curtains

The high strength and diversity of Tricot Fabric also make it widely used in home decoration. As the material of home products such as curtains, sofa covers, bedding, etc., warp knitted fabrics can provide beautiful appearance and excellent durability.

4. Industrial and Functional Fabrics

In some industrial and functional fabric fields, Tricot Fabric is widely used due to its high strength, wear resistance and special functionality (such as UV resistance, flame retardant, etc.). For example, protective clothing, work clothes, car seats, car interiors, etc.

As a new type of textile material, Tricot Fabric will occupy an increasingly important position in the future textile industry with its excellent performance, wide application and continuous innovation. With the advancement of technology and changes in market demand, future warp knitted fabrics will pay more attention to environmental protection, functionality and personalization, further promoting the innovation and development of the textile industry.

English

English Español

Español