The Cornerstone of Warp Knitting: What is Warp Knitting?

In the vast world of textiles, each type of fabric holds its own, each embracing its unique structure and performance. Among these, one type, known as the "King of Warp Knitting Fabrics," boasts a unique loop-forming method and stable structure, earning it the title of "King of Warp Knitting Fabric." This is what we often call warp knitting fabric. The very name itself embodies its unique craftsmanship—"Tricot" comes from the French word for "weaving." Unlike familiar weft-knitted fabrics (such as T-shirt fabric), the production process of warp knitting fabric is more complex and sophisticated, employing a warp knitting method.

Simply put, warp knitting is a process in which yarns in the warp direction (i.e., yarns running parallel to the selvedge) are looped and interwoven to form a fabric. On a warp knitting machine, one or more rows of needles knit simultaneously, each carrying one or more yarns. Under the high-speed operation of the machine, these yarns are knitted into loops through a series of movements, including yarn guiding, yarn bending, and yarn casting, and then interwoven, ultimately forming a single piece of fabric. This unique weaving method gives warp knitted fabrics many distinctive properties.

Its structural stability is exceptional. Because warp knitted fabrics are woven simultaneously from multiple warp yarns, each loop interlocks with the loops above, below, and to the left and right, forming a tight mesh. Even if a single loop of the fabric is damaged, it will not unravel as quickly as in weft knitted fabrics. Even if a cut is made, the extent of the damage is relatively controlled. This high stability makes warp knitted fabrics highly effective in applications requiring high strength and durability.

Warp knitted fabrics generally have greater elasticity than woven fabrics, but are not as flexible as weft knitted fabrics. Its elasticity is typically lower in the longitudinal direction and higher in the transverse direction. This allows it to better conform to the body's curves in clothing applications, providing a comfortable fit without excessive loosening or deformation.

Warp knitted fabric types and applications: From sportswear to high-tech materials

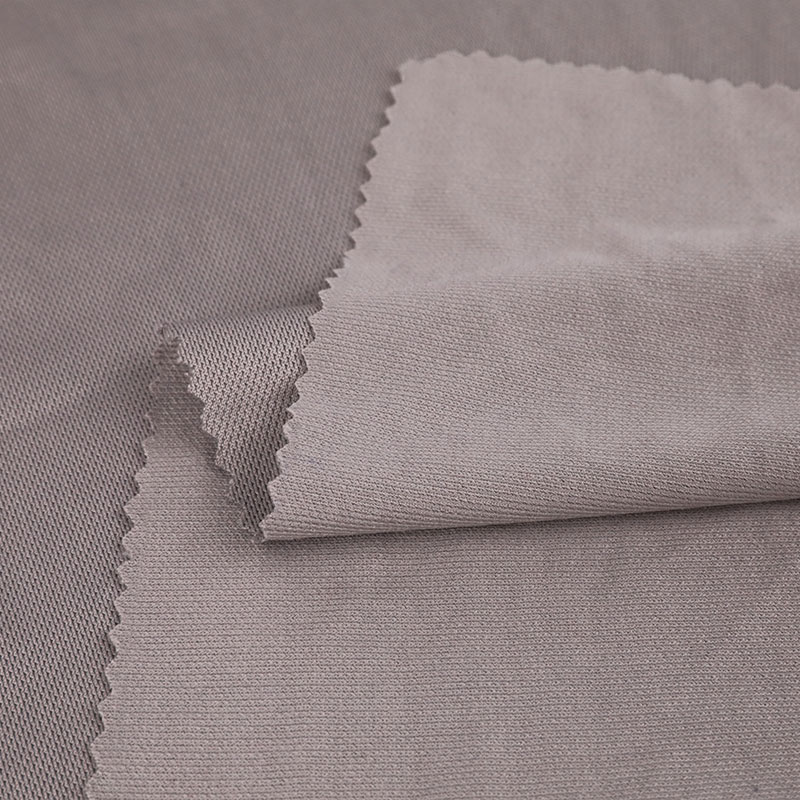

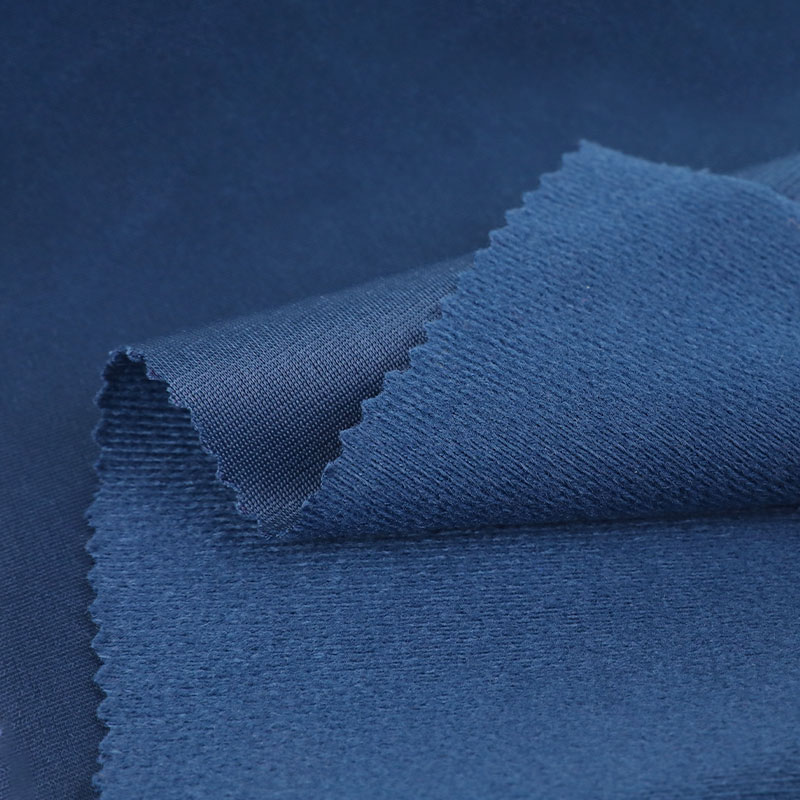

Warp knitted fabrics are not a single fabric. Depending on the raw materials, weaving methods, and finishing processes, warp knitted fabrics can be produced in a wide variety of forms to meet a wide range of application needs.

The most common warp knitted fabric is standard warp knitted fabric, typically made from synthetic fibers such as polyester and nylon. It features a soft feel, a bright luster, and good moisture absorption. This type of fabric is commonly used in sportswear, underwear, swimwear, and other applications because it is not only comfortable to wear, but also easy to wash and quick-drying, making it ideal for active activities involving heavy sweating.

In addition to standard warp knitted fabrics, there are also specialized warp knitted fabrics, such as jacquard warp knitted fabrics. This fabric utilizes jacquard patterning technology, which controls the movement of individual yarns to create complex patterns and designs on the fabric surface, giving it a highly decorative effect. Jacquard warp knitted fabric is commonly used in high-end lingerie, decorative items, and home textiles. Its exquisite patterns and delicate feel make it a valuable option for enhancing product quality.

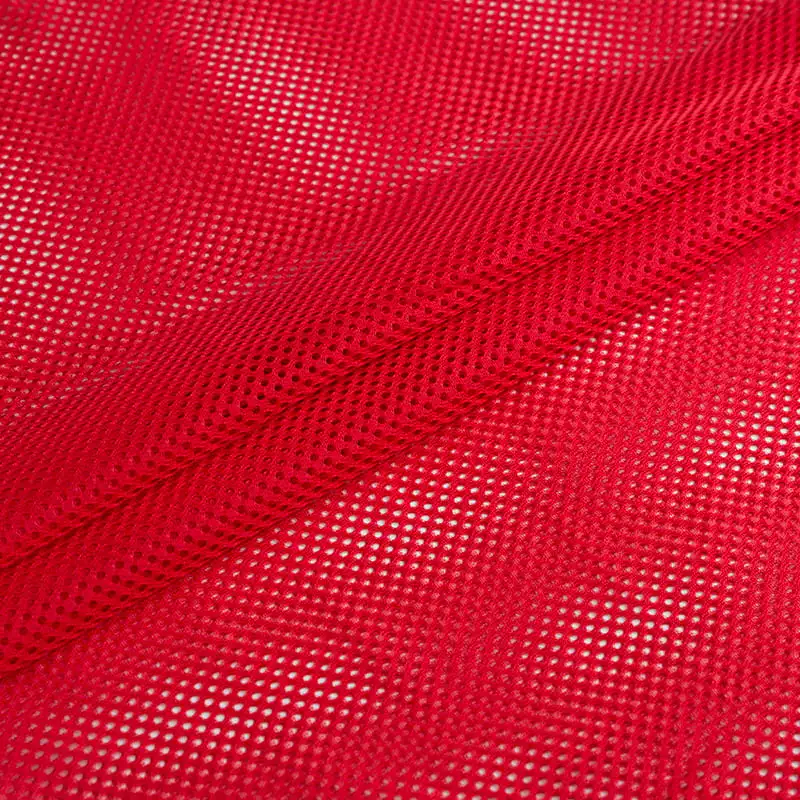

Mesh warp knitted fabric is another important branch of the warp knitted fabric family. Through a special weaving method, a regular mesh of holes is formed on the fabric surface, giving it excellent breathability and a lightweight feel. Mesh warp knitted fabric is widely used in sportswear, luggage, and footwear. In sportswear, it helps sweat evaporate quickly, keeping the body dry; in luggage and footwear, it reduces weight while increasing breathability and enhancing comfort.

With technological advances, the application of warp knitted fabric has expanded far beyond traditional clothing and home textiles. Using specialized yarns and weaving techniques, warp knitted fabrics can be imbued with a variety of high-tech properties. For example, warp knitted fabrics woven with conductive fibers can be used in smart wearable devices as sensors or conductive pathways, while warp knitted fabrics woven with flame-retardant fibers can be used in protective clothing to provide fire protection. Warp knitted fabrics are even finding use in the medical field, for example as materials for artificial blood vessels or surgical implants, where their excellent biocompatibility and stable structure make them an ideal choice.

Warp Knitted Fabric Production Process and Technological Innovation

Warp knitting fabric production is a sophisticated system that relies on advanced warp knitting machines and sophisticated craftsmanship. A warp knitting machine typically consists of several components, including a let-off mechanism, a weaving mechanism, and a take-up and reel mechanism. The let-off mechanism is responsible for evenly feeding the yarn to the weaving area; the weaving mechanism is the core of the entire machine, controlling the needles, latches, and yarn guides through a complex linkage mechanism to complete a series of operations such as loop formation and threading; the take-up and reel mechanism is responsible for evenly winding the woven fabric into rolls.

With technological advances, warp knitting machines are becoming increasingly automated, and production efficiency is increasing. Modern warp knitting machines can reach speeds of thousands of revolutions per minute, significantly shortening production cycles. Furthermore, the emergence of multi-bar warp knitting machines has enabled a greater variety of warp knitted fabric structures and patterns. By increasing the number of bars, more yarns can be knitted simultaneously, creating more complex and layered fabrics.

In addition to advances in machinery, innovations in raw materials have also injected new vitality into the development of warp knitted fabrics. New functional fibers, such as moisture-wicking fibers, antibacterial and deodorizing fibers, and far-infrared fibers, are widely used in the production of warp knitted fabrics. These functional fibers, combined with the unique structure of warp knitted fabrics, can create products with added value, such as sportswear and underwear with multiple functions such as warmth, antibacterial properties, and UV protection.

Looking to the Future: The Infinite Possibilities of Warp Knitted Fabrics

As a prominent representative of warp knitted fabrics, warp knitted fabrics, with their unique weaving method, stable structure, and diverse applications, occupy a pivotal position in the textile market.

From a simple T-shirt to high-tech smart wearables, warp knitted fabrics, with their unique charm and unlimited potential, are constantly expanding our imagination of textiles. More than just a fabric, they serve as a bridge connecting traditional craftsmanship with modern technology. With their tenacity and agility, they weave the fabrics of our future lives.

English

English Español

Español