In the ever-evolving textile industry, innovation is key to meeting the demands of modern consumers and industrial applications. One such groundbreaking material is Superpoly Knitting Tricot Brushed Fabric, a high-performance textile that combines durability, comfort, and versatility. This fabric is rapidly gaining traction in fashion, sportswear, medical textiles, and even automotive interiors due to its unique properties.

But what exactly makes Superpoly Knitting Tricot Brushed Fabric stand out?

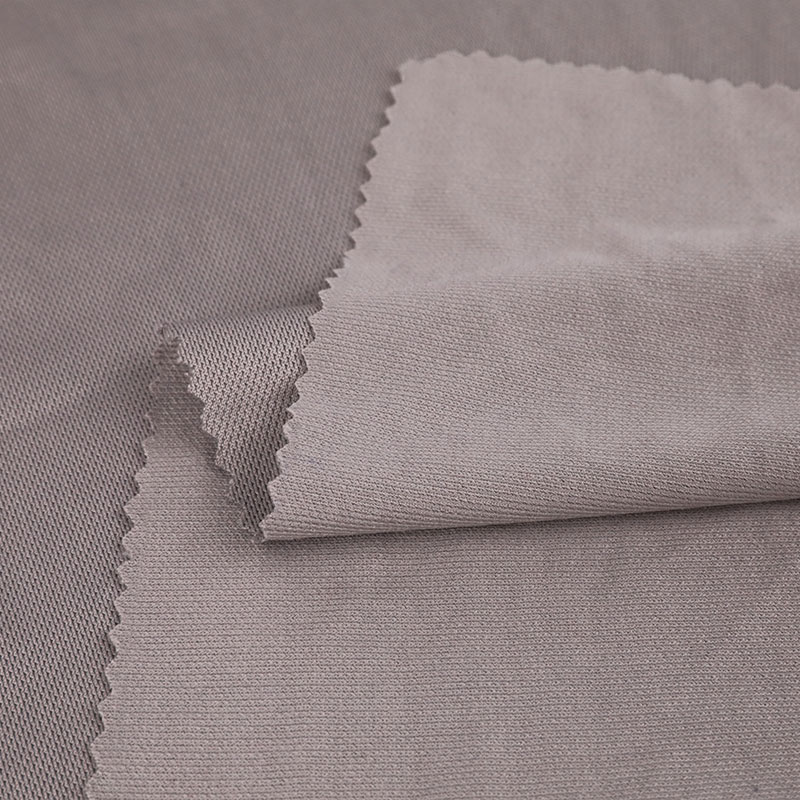

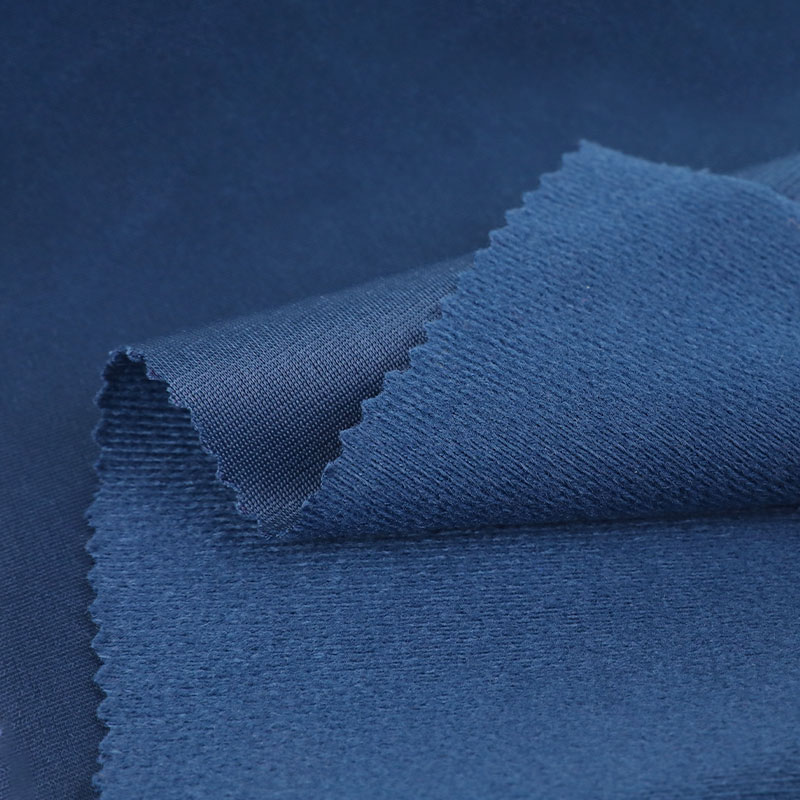

Superpoly Knitting Tricot Brushed Fabric is a specialized knitted textile made from high-quality polyester (Superpoly) fibers, processed using a tricot knitting technique and finished with a brushing treatment.

Superpoly (Super Polyester): A premium-grade polyester variant known for enhanced strength, elasticity, and moisture-wicking capabilities.

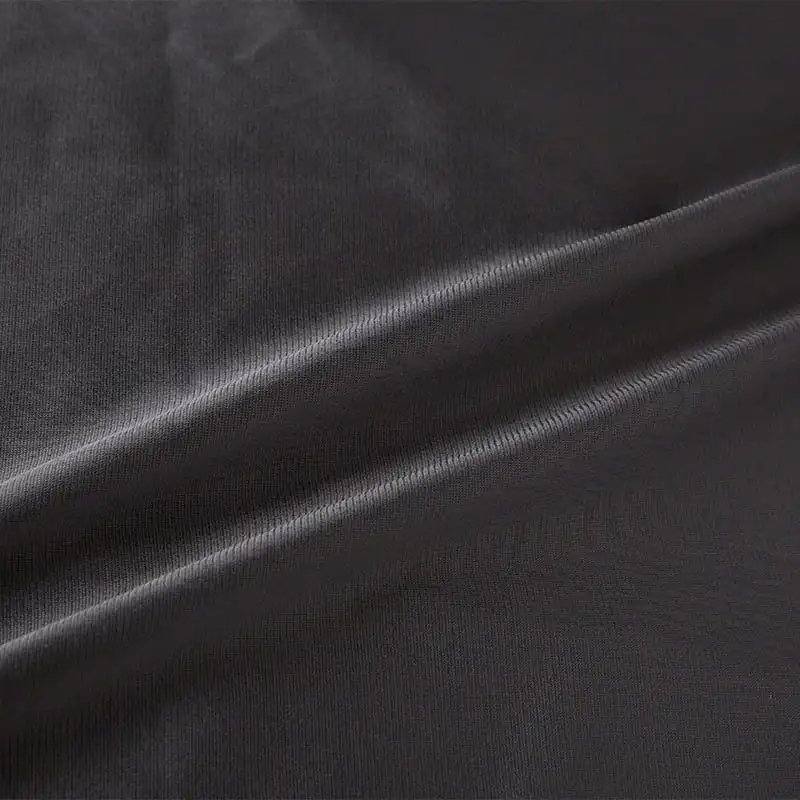

Tricot Knitting: A warp-knitting method that produces a fine, stable, and stretchable fabric with a smooth surface.

Brushed Finish: A mechanical process where the fabric surface is lightly abraded to create a soft, fuzzy texture, improving comfort and insulation.

This combination results in a fabric that is lightweight, breathable, durable, and exceptionally soft—making it ideal for a wide range of uses.

Manufacturing Process: How Is It Made?

The production of Superpoly Knitting Tricot Brushed Fabric involves several precise steps:

1. Yarn Formation

High-tenacity polyester filaments are spun into fine, uniform yarns.

The yarn may be texturized for added stretch and bulk.

2. Tricot Knitting

The yarn is fed into a tricot knitting machine, which interloops the threads in a zigzag pattern.

This creates a fabric with excellent dimensional stability and minimal fraying.

3. Brushing Process

The knitted fabric passes through rotating brushes that raise the fibers, creating a plush, velvety surface.

This enhances thermal insulation and provides a luxurious hand feel.

4. Finishing Treatments

Depending on the intended use, the fabric may undergo:

Anti-pilling treatment (for long-term smoothness)

Moisture-wicking coatings (for sportswear)

Flame-retardant finishes (for automotive and industrial uses)

Key Benefits of Superpoly Knitting Tricot Brushed Fabric

1. Superior Comfort & Softness

The brushed finish gives it a cashmere-like feel, making it ideal for loungewear and intimate apparel.

2. Enhanced Durability

Polyester’s inherent strength ensures resistance to wear, stretching, and pilling.

Tricot knitting adds structural integrity, preventing runs and snags.

3. Moisture Management & Breathability

The fabric’s open-knit structure allows air circulation, reducing sweat buildup.

Ideal for athletic wear and performance garments.

4. Thermal Regulation

The brushed fibers trap air, providing lightweight warmth—perfect for thermals and winter activewear.

5. Versatility in Applications

Fashion: Dresses, leggings, scarves, and lingerie.

Sportswear: Yoga pants, running tops, and compression wear.

Medical & Hygiene: Bandages, surgical drapes (due to its hypoallergenic nature).

Automotive: Seat covers, headliners, and interior linings.

Superpoly Knitting Tricot Brushed Fabric represents the perfect fusion of technology and comfort, making it a top choice for modern textiles. Whether in high-fashion, performance wear, or industrial applications, its softness, durability, and functionality set it apart from traditional materials.

As innovation continues, we can expect even more sustainable and high-performance variants of this fabric, solidifying its place as a textile of the future.

English

English Español

Español