I. Basic Concepts and Definitions of Super Poly Fabric

1.1 Fiber Composition and Chemical Basis

Super Poly Fabric is essentially a high-performance fabric based on polyester fiber (Polyester). Polyester fiber is made of organic dibasic acid and diol through polycondensation reaction, and this chemical structure gives it many unique properties. In Super Poly Fabric, polyester fiber is further modified and optimized. By adding special additives, changing the polymerization process or performing physical treatment, its performance exceeds that of ordinary polyester fiber. For example, by controlling the length and structure of the molecular chain, the strength and modulus of the fiber can be improved; by introducing specific functional groups, the hygroscopicity and dyeability of the fiber can be improved.

1.2 Differences from traditional polyester fiber fabrics

Although traditional polyester fiber fabrics have the advantages of high strength, wrinkle resistance, wear resistance, easy washing and quick drying, they also have disadvantages such as poor hygroscopicity, poor breathability, and not soft enough feel. Super Poly Fabric is committed to overcoming these shortcomings. In terms of hygroscopicity, by special treatment of the fiber surface or the use of new hydrophilic modification technology, it can absorb and conduct more moisture, making the wearer feel more comfortable. In terms of hand feel, advanced finishing processes such as softener treatment and mechanical softening processing are used to make the fabric have a soft touch closer to natural fibers (such as cotton and silk). In terms of breathability, by optimizing the arrangement of fibers and developing a special fabric structure, the air circulation is enhanced, breaking the limitation of the stuffiness of traditional polyester fiber fabrics.

2. Characteristics and advantages of Super Poly Fabric

2.1 Strong mechanical properties

2.1.1 High strength and high modulus

Super Poly Fabric has excellent strength and modulus. Its high strength makes the fabric not easy to break when subjected to large external forces, and can adapt to various high-intensity usage scenarios. For example, in the field of industrial protection, protective clothing made of Super Poly Fabric can effectively resist puncture and friction from sharp objects, providing reliable protection for workers. High modulus ensures that the fabric is not easy to deform when subjected to force and has good dimensional stability. Taking automobile airbags as an example, Super Poly Fabric can withstand huge impact forces in an instant, quickly deploy and maintain its shape, providing safety protection for passengers. This high strength and high modulus characteristics are derived from its optimized fiber structure and tight molecular arrangement, which makes the bonding between fibers stronger and can resist external forces together.

2.1.2 Excellent wear resistance

Abrasion resistance is a major advantage of Super Poly Fabric. In daily use, fabrics often rub against various objects, and Super Poly Fabric can withstand long-term and high-intensity friction tests. In outdoor sportswear, when people are engaged in activities such as mountaineering and hiking, clothes frequently rub against rocks, branches, etc. Clothing made of Super Poly Fabric is not easy to wear, which greatly extends the service life of clothing. This is because the fiber surface has been specially treated to increase the hardness, and the friction between fibers is small, which reduces fiber damage and shedding caused by friction. At the same time, the special fiber structure enables the fabric to better disperse stress when it is rubbed, avoiding local excessive wear.

2.2 Excellent chemical stability

2.2.1 Chemical corrosion resistance

Super Poly Fabric has good tolerance to most chemicals. Whether it is common chemical reagents such as acids and alkalis, or some organic solvents, it is difficult to cause obvious corrosion and damage to it. In the chemical industry, workers wearing work clothes made of Super Poly Fabric can effectively protect against the erosion of various chemicals and ensure work safety. This is due to the chemical structure stability of polyester fiber itself, and the ester bonds in its molecular chain have a certain resistance to chemicals. At the same time, in the preparation process of Super Poly Fabric, some additives with chemical corrosion resistance may be added to further enhance its chemical corrosion resistance.

2.2.2 Anti-ultraviolet performance

Ultraviolet rays can cause damage to many fabrics, causing fading, aging and other problems. Super Poly Fabric has excellent anti-ultraviolet performance by adding special anti-ultraviolet agents or using fiber modification technology with anti-ultraviolet function. In outdoor products, such as parasols, outdoor furniture covers, etc., Super Poly Fabric can effectively block the penetration of ultraviolet rays, protect users from ultraviolet damage, and keep the color and performance of the fabric stable. Anti-ultraviolet agents can absorb or reflect ultraviolet rays, convert the energy of ultraviolet rays into other forms of energy and release them, thereby reducing damage to the fiber.

2.3 Excellent functionality

2.3.1 Moisture absorption and perspiration function

Super Poly Fabric's moisture absorption and perspiration function makes it popular in the field of sports and outdoor clothing. It can quickly absorb sweat from the human body surface and quickly conduct the sweat to the surface of the fabric, dissipate it through evaporation, and keep the skin dry. During strenuous exercise, the human body will sweat a lot. If the sweat cannot be discharged in time, it will make people feel stuffy and uncomfortable, and may even cause diseases such as colds. Sportswear made of Super Poly Fabric can solve this problem and keep athletes comfortable during exercise. This function is achieved on the one hand because the fiber is hydrophilic modified, the hydrophilic groups on the fiber surface are increased, and the fiber's ability to absorb moisture is improved; on the other hand, by designing a special fabric structure, a channel for rapid moisture conduction is formed, which accelerates the discharge of sweat.

2.3.2 Waterproof and breathable function

Some Super Poly Fabrics also have waterproof and breathable properties. In terms of waterproofing, by waterproofing the fiber surface or using special coating technology, the fabric can prevent water droplets from penetrating, keeping the inside dry even in rainy days or humid environments. At the same time, the fabric has good breathability, which can smoothly discharge the heat and moisture generated by the human body. In outdoor adventure activities, wearing Super Poly Fabric clothing with waterproof and breathable functions can not only resist the invasion of rain, but also not feel stuffy. The waterproof function mainly relies on the waterproof coating or the low surface energy treatment of the fiber surface, so that water droplets form water beads on the surface of the fabric and roll off. The breathable function controls the micropore size of the coating or uses a special fabric structure to allow gas molecules to pass freely while preventing the entry of liquid water.

3. Manufacturing process of Super Poly Fabric

3.1 Raw material selection and pretreatment

3.1.1 Selection of polyester chips

The manufacturing of Super Poly Fabric starts with the selection of polyester chips. High-quality polyester chips are the basis for ensuring the performance of fabrics. Manufacturers will strictly screen the purity, molecular weight distribution, end group content and other indicators of polyester chips. High-purity polyester chips have fewer impurities and can ensure the uniformity and stability of the fiber during the spinning process. Appropriate molecular weight distribution affects the strength, toughness and other properties of the fiber. By testing and analyzing the performance of polyester chips from different batches and different manufacturers, the most suitable raw materials for the production of Super Poly Fabric are selected. For example, for Super Poly Fabric that requires high strength performance, polyester chips with higher molecular weight and narrower molecular weight distribution will be selected to ensure that the fiber has higher strength and modulus.

3.1.2 Addition of additives and modifiers

In order to give Super Poly Fabric special properties, various additives and modifiers are added during the raw material pretreatment stage. For example, in order to improve the UV resistance of the fiber, ultraviolet absorbers are added; in order to improve the hygroscopicity of the fiber, hydrophilic agents are added; in order to enhance the flame retardant properties of the fiber, flame retardants are added. The amount of these additives and modifiers added needs to be precisely controlled, and too much or too little will affect the final performance of the fabric. The addition process is usually carried out in the melting stage of the polyester chips. Through high-speed stirring or special mixing equipment, the additives and modifiers are evenly dispersed in the polyester melt, ensuring that they can be evenly distributed inside the fiber during the subsequent spinning process and play their due role.

3.2 Spinning process

Melt spinning is one of the commonly used spinning methods in Super Poly Fabric production. The pretreated polyester chips are heated to a molten state, and the melt is extruded through the small holes on the spinneret by a screw extruder to form filaments. During the spinning process, parameters such as temperature, pressure, and spinning speed need to be precisely controlled. Too high a temperature will cause the polyester melt to degrade and affect the fiber properties; too low a temperature will make the melt fluidity worse and difficult to extrude smoothly. Stable pressure is crucial to ensure the uniformity of the fiber, and the spinning speed determines the thickness and production efficiency of the fiber. For example, when producing ultra-fine denier Super Poly Fabric fibers, higher spinning speeds and more precise temperature and pressure control are required to ensure that the fiber diameter is uniform and reaches the expected fineness.

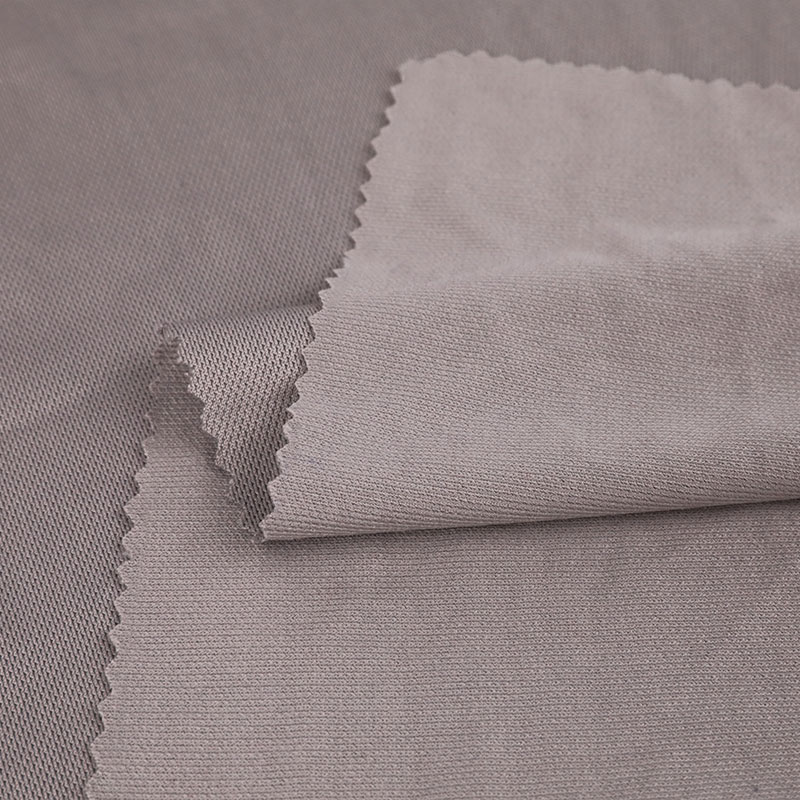

3.3 Finishing Process

3.3.1 Softening Finishing

Softening finishing is an important part of the finishing process of Super Poly Fabric, which aims to improve the feel of the fabric and make it softer and more comfortable. Common softening finishing methods include chemical softener treatment and mechanical softening treatment. Chemical softeners reduce the friction between fibers by physical or chemical action on the fiber surface, making the fabric feel soft. Mechanical softening treatment achieves a softening effect by mechanical rubbing, beating, etc., which causes the fibers to deform and relax to a certain extent. In actual production, chemical softener treatment and mechanical softening treatment are usually combined. The fabric is first impregnated or coated with a chemical softener, and then processed with a mechanical softening device to obtain the best softening effect. Different types of Super Poly Fabric will choose different softeners and mechanical processing parameters according to their uses and fiber characteristics.

3.3.2 Functional finishing (waterproof, antibacterial, etc.)

In order to give Super Poly Fabric more functionality, corresponding functional finishing will be carried out. In terms of waterproof finishing, coating or impregnation is mainly used. The coating method is to apply a layer of waterproof coating agent on the surface of the fabric to form a continuous waterproof film to prevent water from penetrating. The impregnation method is to soak the fabric in a waterproofing agent solution, so that the waterproofing agent penetrates into the fiber and forms a waterproof protective film on the fiber surface. Antibacterial finishing usually uses antibacterial agents to treat the fabric. Antibacterial agents can inhibit or kill bacteria, fungi and other microorganisms on the surface of the fabric to prevent the fabric from producing odor and mildew. For some Super Poly Fabrics that require special functions, anti-fouling finishing, anti-static finishing, etc. may also be performed. The selection and implementation of these functional finishing processes need to be customized according to the final use of the fabric and customer needs to ensure that the fabric has the required functions and the performance is long-lasting and stable.

4. Application of Super Poly Fabric in Different Fields

4.1 Fashion and Clothing Fields

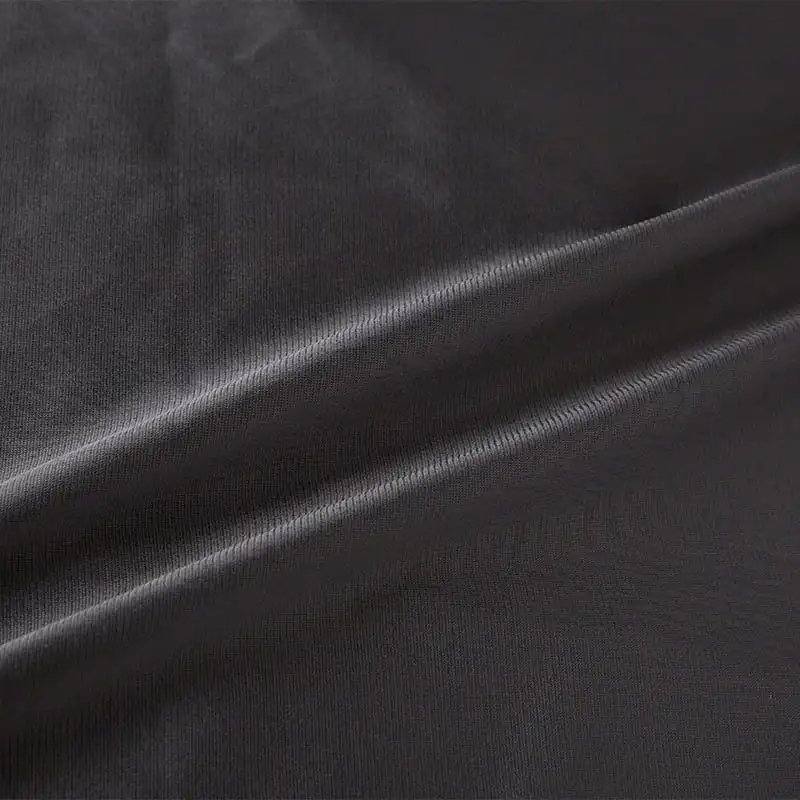

4.1.1 High-end Sportswear

Super Poly Fabric has a wide range of applications in the field of high-end sportswear. Its excellent moisture absorption and perspiration wicking function can quickly expel the sweat produced by athletes during exercise, keep the body dry, and improve sports comfort. For example, Super Poly Fabric is widely used in professional running, basketball, football and other sportswear. It not only meets the functional needs of athletes for clothing, but also has good wear resistance and tensile strength, can withstand high-intensity sports movements, and is not easy to deform and damage. At the same time, Super Poly Fabric can obtain various textures and appearance effects through special finishing processes to meet the needs of fashion design, making sportswear both high-performance and fashionable.

4.1.2 Outdoor Adventure Clothing

For outdoor adventure enthusiasts, clothing made of Super Poly Fabric is an ideal choice. In outdoor environments, there are various complex weather conditions and terrain challenges. The waterproof and breathable function of Super Poly Fabric can effectively resist the invasion of rain, while ensuring that the heat and moisture generated by the body can be discharged in time to avoid physical discomfort caused by humidity and stuffiness. Its anti-ultraviolet performance can protect the skin from ultraviolet damage and extend the service life of clothing. In outdoor activities such as mountaineering, hiking, and camping, the high strength and wear resistance of Super Poly Fabric can also withstand the friction and scratches of rocks, branches, etc., providing reliable protection for explorers. Moreover, outdoor adventure clothing usually needs to be lightweight. The relatively light weight of Super Poly Fabric will not add too much burden to explorers, allowing them to move more freely.

4.2 Industry and protection field

4.2.1 Industrial protective clothing

In industrial production, workers face various potential dangers, such as mechanical injuries, chemical corrosion, high temperature burns, etc. Super Poly Fabric has become an ideal material for making industrial protective clothing due to its high strength, wear resistance, and chemical corrosion resistance. For example, in industries such as automobile manufacturing and mechanical processing, workers may come into contact with sharp tools and parts. Protective clothing made of Super Poly Fabric can effectively prevent punctures and scratches. In the chemical industry, protective clothing needs to have good chemical corrosion resistance, Super Poly Fabric can resist the erosion of acid, alkali and other chemical substances, protecting the physical safety of workers. Some Super Poly Fabrics can also be specially treated to have flame retardant, anti-static and other functions to meet the protection needs of different industrial environments.

4.2.2 Safety protection equipment

Super Poly Fabric also has important applications in the field of safety protection equipment. In protective equipment such as bulletproof vests and helmets, the use of high-strength Super Poly Fabric fibers can effectively absorb and disperse bullets or other impact forces, providing reliable protection for users. Its lightweight characteristics also enable protective equipment to reduce the burden on the wearer while ensuring protective performance and improve the flexibility of action. In some public safety fields, such as riot shields and safety nets, Super Poly Fabric also plays an important role. Its high strength and durability can ensure that protective equipment plays a role at critical moments and protect the lives of personnel.

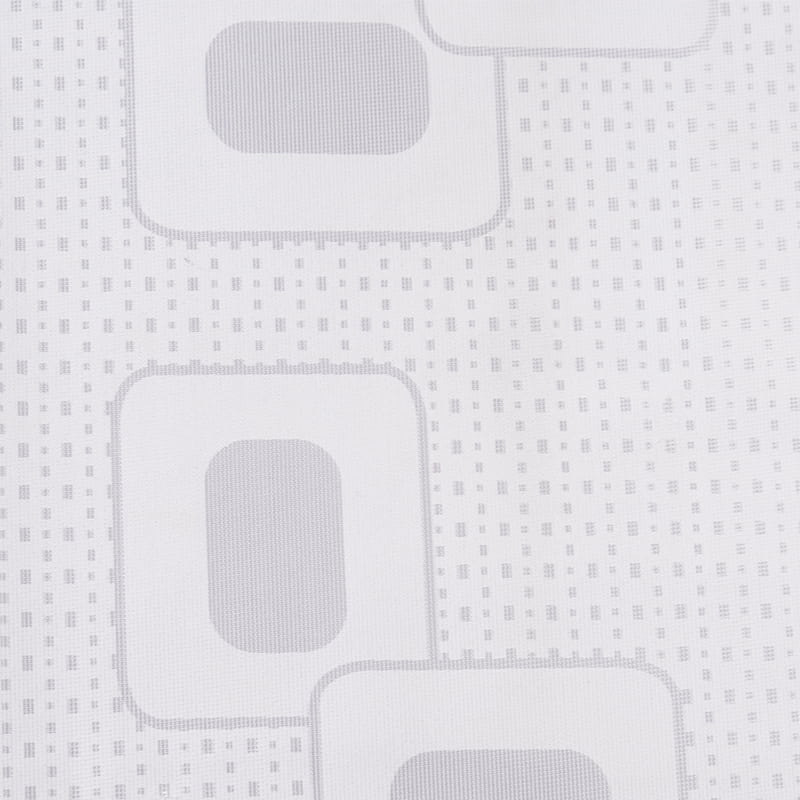

4.3 Home and interior decoration field

4.3.1 Furniture fabrics

Super Poly Fabric has unique advantages in home furniture fabrics. Its wear resistance enables furniture fabrics to withstand friction and wear in daily use, extending the service life of furniture. For example, in the fabric selection of furniture such as sofas and chairs, Super Poly Fabric can resist the friction caused by frequent sitting and moving of the human body, and is not easy to pilling and wear. At the same time, through special dyeing and printing processes, Super Poly Fabric can present a variety of colors and patterns to meet the decoration needs of different home styles. In addition, some Super Poly Fabrics are also resistant to stains and easy to clean, which is very practical for families with children and pets. It can easily deal with daily stains and dust and keep the furniture clean and beautiful.

4.3.2 Curtains and bedding

In the field of curtains and bedding, Super Poly Fabric is also gradually gaining popularity. For curtains, its anti-ultraviolet performance can effectively block ultraviolet rays in the sun, protect indoor furniture and decorations from damage by ultraviolet rays, and extend the service life of the curtains themselves. The waterproof performance of Super Poly Fabric can make the curtains resist rain splashing to a certain extent and keep the room dry. When making bedding, the soft touch and moisture absorption and perspiration function of Super Poly Fabric can provide a comfortable sleeping environment for sleepers, allowing people to stay dry and comfortable during sleep. Moreover, Super Poly Fabric has good dimensional stability and is not easily deformed after multiple washings, and can always maintain a good use condition.

V. Market Status and Development Trend of Super Poly Fabric

5.1 Market Size and Growth Trend

At present, the Super Poly Fabric market is showing a steady growth trend. With the increasing demand for high-performance fabrics and the continuous expansion of its applications in various fields, the market size of Super Poly Fabric continues to expand. In the field of fashion and clothing, consumers' pursuit of the functionality of sportswear and outdoor clothing has promoted the growth of Super Poly Fabric applications in this field. In the field of industry and protection, the improvement of safety awareness and the improvement of performance requirements for protective equipment have led to an increasing demand for Super Poly Fabric in industrial protective clothing and safety protection equipment. In the field of home and interior decoration, consumers' emphasis on the quality and aesthetics of household products also provides a broad market space for the application of Super Poly Fabric. It is expected that the Super Poly Fabric market will continue to maintain a high growth rate in the next few years, especially in emerging markets and developing countries. With the development of the economy and the improvement of people's living standards, the demand for Super Poly Fabric products will be further released.

5.2 Future Development Trends

5.2.1 Technological Innovation and Performance Improvement

In the future, Super Poly Fabric will develop in the direction of technological innovation and performance improvement. In terms of fiber manufacturing technology, new polyester fiber modification methods will be continuously developed to further improve the fiber's strength, modulus, moisture absorption and perspiration performance, waterproof and breathable performance, etc. For example, the fiber is modified by nanotechnology to form a nano-scale structure on the fiber surface, thereby enhancing the functionality of the fiber. In terms of manufacturing technology, the spinning process and finishing process will be continuously optimized to improve production efficiency, reduce production costs, and improve the stability of product quality.

5.2.2 Sustainable development and environmental protection requirements

As the world's attention to environmental protection and sustainable development continues to increase, Super Poly Fabric will also face higher environmental protection requirements. In the future, manufacturers will pay more attention to the sustainability of raw materials and develop and use recyclable and degradable polyester fiber raw materials. In the production process, more environmentally friendly production processes will be adopted to reduce energy consumption and pollutant emissions. For example, green spinning technology and waterless dyeing technology will be developed. At the same time, the management of product life cycle will be strengthened. From raw material procurement, production and processing, product use to waste disposal, the principle of sustainable development will be followed to achieve green development of Super Poly Fabric industry. In terms of market demand, consumers' recognition and demand for environmentally friendly Super Poly Fabric products will continue to increase, driving the transformation of the entire industry towards sustainable development.

English

English Español

Español