At the core of every 100% Polyester Fabric Factory is the transformation of raw polyester fibers into the fabric we know. The factory starts with the procurement of high-quality polyester fibers, usually derived from petrochemical sources. These fibers undergo a series of processes, including extrusion, spinning, and texturing, to create the base material for polyester fabric.

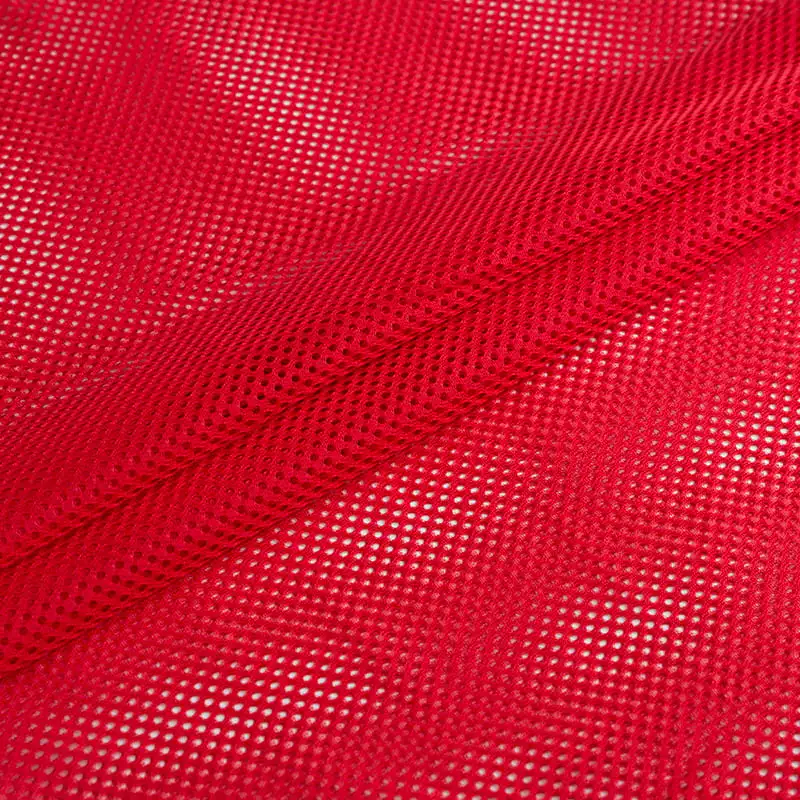

The weaving or knitting process is a critical stage in the creation of polyester fabric. In a 100% Polyester Fabric Factory, advanced machinery is employed to interlace or loop polyester yarns, creating a strong and durable textile. The choice between weaving and knitting depends on the desired characteristics of the final fabric, with weaving offering stability and knitting providing flexibility.

Once the fabric is woven or knitted, it undergoes dyeing and finishing processes. A 100% Polyester Fabric Factory utilizes various techniques to impart color to the fabric, ranging from traditional dyeing methods to advanced printing technologies. The finishing stage involves treatments to enhance the fabric's feel, texture, and performance characteristics, ensuring it meets the desired specifications.

Quality control is a paramount aspect of any reputable 100% Polyester Fabric Factory. Rigorous testing procedures are implemented throughout the manufacturing process to ensure that the fabric meets established standards for strength, colorfastness, shrink resistance, and other crucial parameters. This commitment to quality assurance guarantees that the end product is consistent and reliable.

Versatility is a hallmark of polyester fabric, and a 100% Polyester Fabric Factory caters to diverse industries. Whether it's fashion, home textiles, automotive, or industrial applications, these factories can customize the fabric to meet specific requirements. This adaptability makes polyester fabric a preferred choice in a wide array of end-use applications.

In response to growing environmental concerns, many 100% Polyester Fabric Factories are adopting eco-friendly practices. This includes recycling and reducing waste, using sustainable energy sources, and exploring alternative polyester production methods. The integration of environmentally conscious practices ensures that polyester fabric production aligns with global sustainability goals.

A 100% Polyester Fabric Factory often operates within a global supply chain, catering to a diverse clientele across borders. This international reach allows for the seamless exchange of polyester fabric to meet the demands of various markets and industries. The interconnectedness of these factories contributes to the globalization of the textile industry.

English

English Español

Español