Polyester is the world’s most common synthetic fiber and has been the fastest-growing fiber since 1980, according to the Textile Exchange Preferred Fiber Materials Report 2017. It is used in a wide range of applications from technical textiles to sportswear.

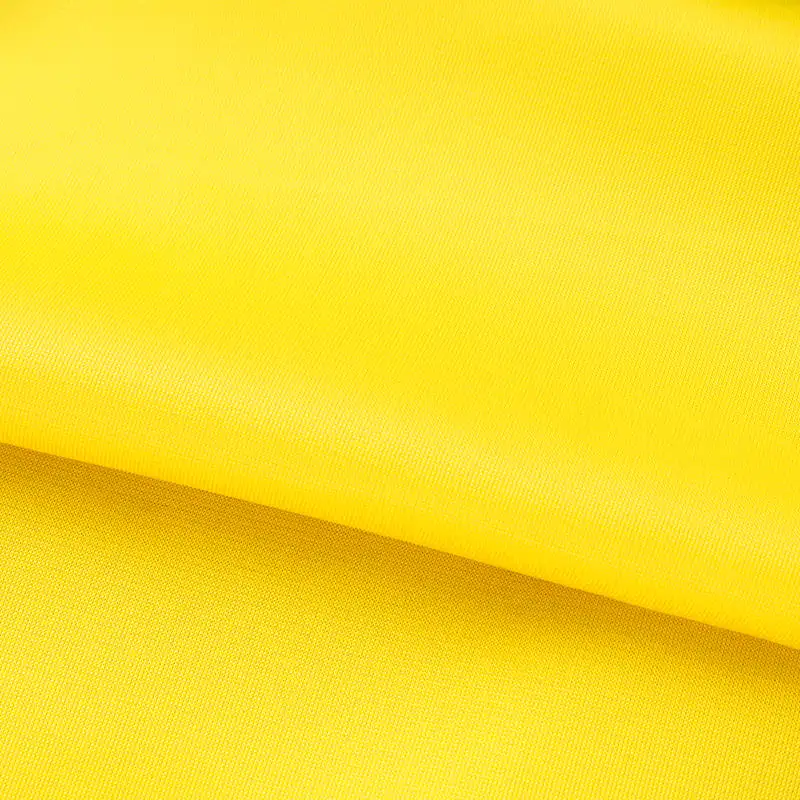

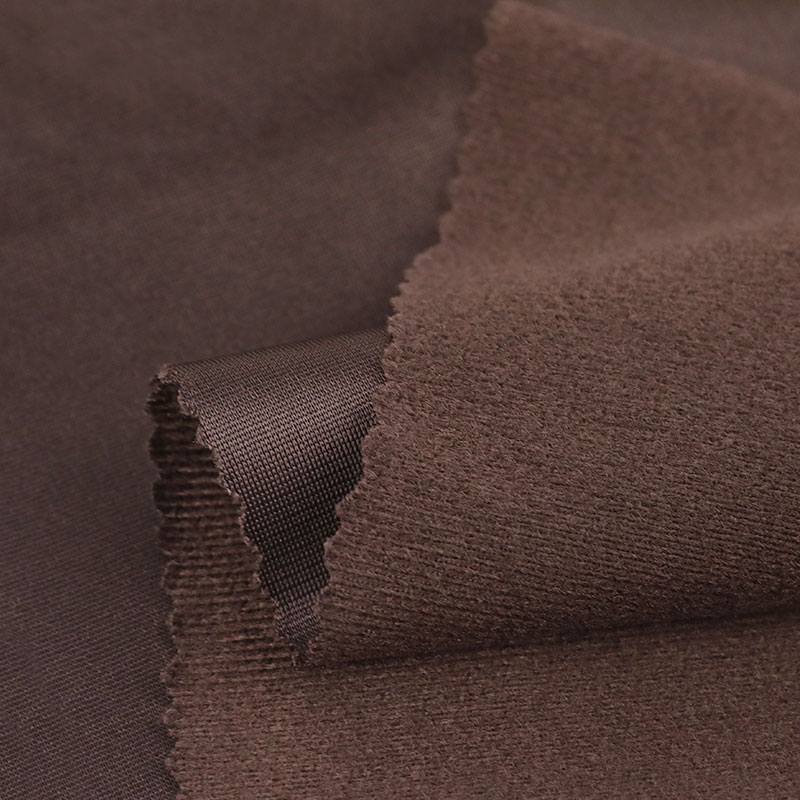

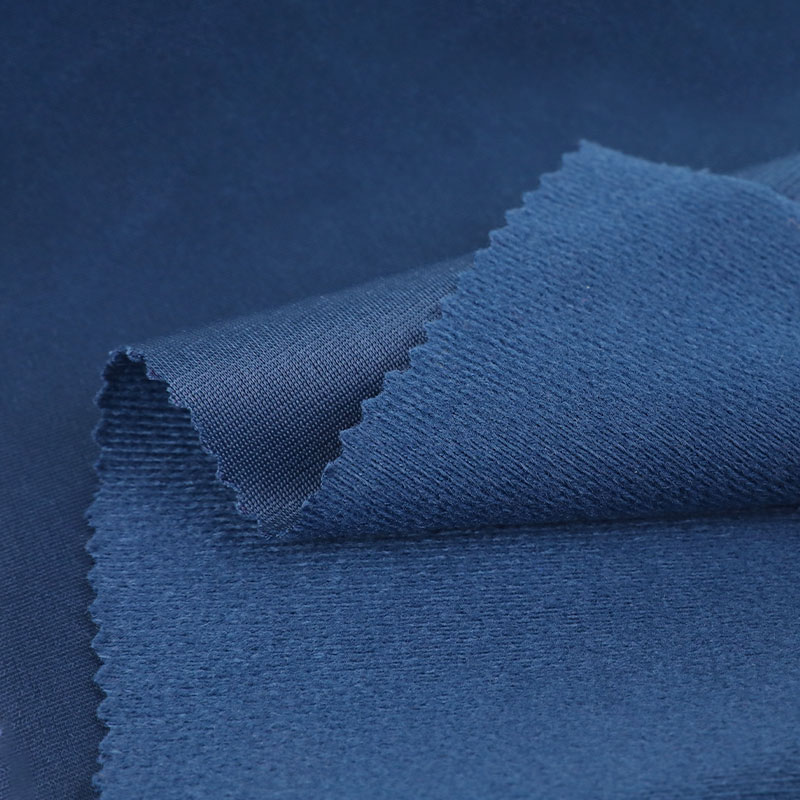

It is a soft, lightweight, non-allergenic and non-pilling fabric that can be woven or knitted to form many different textures and compositions. It is also moisture wicking, wrinkle resistant and highly durable, making it a popular choice for the apparel industry.

The production of polyester involves the extraction of crude oil, chemically refining it to make polymers and extruding these into fibers through spinning. These processes consume a lot of energy, water, and chemicals and release pollutants and greenhouse gases into the atmosphere. This contributes to the global plastic waste and microfiber pollution crisis that pollutes our waterways, kills land and marine wildlife and endangers human health.

Manufacturing polyester uses a variety of toxic chemicals including chlorine, formaldehyde, antimony and lead. Some of these chemicals are carcinogenic and may cause respiratory illness, such as asthma or rhinitis.

Most textile dyes and bleaches contain toxic heavy metals such as cadmium and chromium, which can be hazardous to our health. Additionally, most of the cotton used in the garment industry is made from pesticide-treated seed and has been treated with harmful chemicals.

The manufacture of polyester uses a significant amount of energy and creates significant waste throughout the process. In addition, it takes more than 200 years for polyester to decompose in landfills and more than 85% of all textiles that are thrown away are dumped into landfills or burned.

In fact, many fashion brands are now trying to reduce their impact on the environment by promoting more sustainable clothing options. One of the most popular is the use of recycled polyester. However, there is an issue with the way that used clothing is recycled. While there are recycling programs in place for used polyester clothes, less than 1% of the collected materials are actually recycled back into new fabrics or clothes.

It is also difficult to separate poly-blends from 100% polyester and recycle them as a single product. The recycling of poly-blends is an ongoing challenge for the fashion industry, and manufacturers are working hard to find ways to separate these two products.

Despite these challenges, polyester has become an important part of the fast-fashion world, as it is affordable and durable. It’s also available in a variety of colors, patterns, and compositions, making it versatile for many different applications.

The most common uses for polyester are in the apparel industry and industrial applications. It can be woven or knitted to form a variety of types of products, such as coats, jackets, pants, and shirts. It is also commonly used in the manufacturing of household products, such as pillowcases, blankets and curtains.

Polyester has many advantages over natural fibers such as cotton, including being cost-effective, versatile and durable. It can be woven or knitted and has many properties that make it ideal for both indoor and outdoor apparel.

English

English Español

Español