In the modern textile industry, tricot fabric, with its exceptional structural stability, delicate appearance, and superior functional properties, has become a highly sought-after high-performance fabric in the knitting sector. It is widely used in apparel, home textiles, sportswear, and industrial applications, embodying the fusion of high-tech textiles and fashionable design.

I. Tricot Fabric Weaving Principles and Structural Characteristics

Tricot fabric is a type of warp knitted fabric. Warp knitting machines interweave yarns arranged in the warp direction to form a loop structure. Unlike weft knitting, the loops in tricot are arranged diagonally, resulting in a dense fabric structure and a smooth surface, offering exceptional dimensional stability and resistance to deformation. During the weaving process, the yarns are controlled by multiple yarn guides, with each yarn interlaced in a specific pattern, creating the unique warp knit texture.

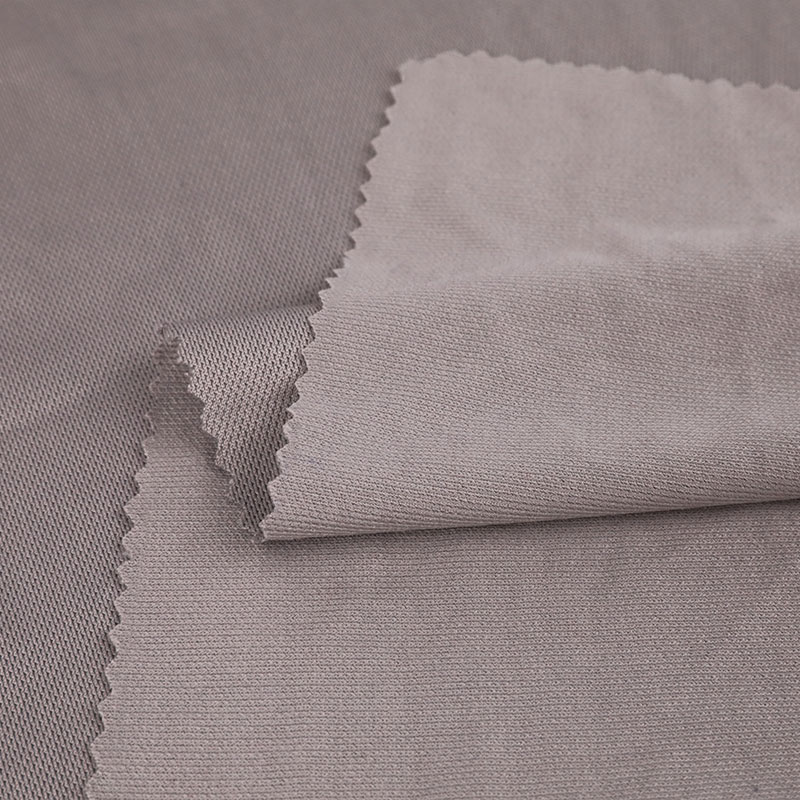

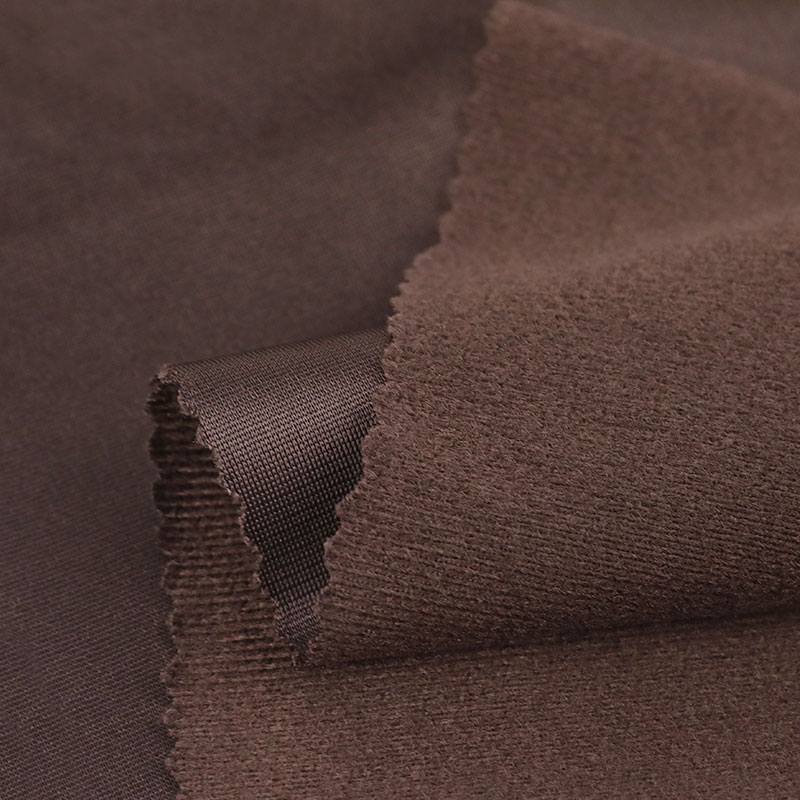

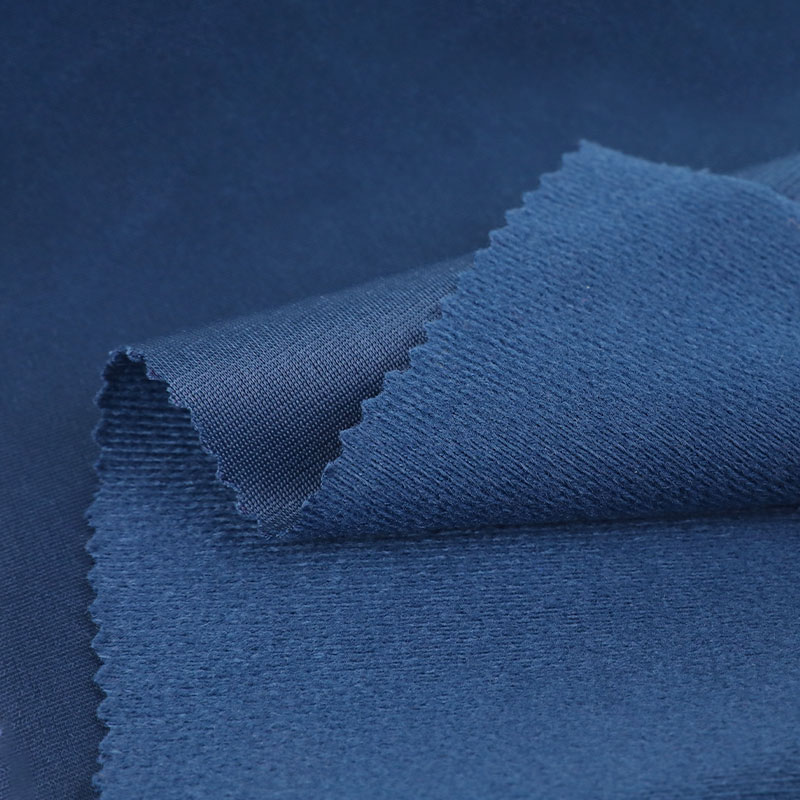

Typical characteristics of tricot fabric include uniform surface density, a fine texture, and moderate elasticity. Its surface typically exhibits smooth longitudinal stripes, while the backside features subtle transverse graining. This structure imparts both stiffness and flexibility. Because Tricot fabric utilizes multiple warp yarns woven in parallel, it resists snagging better than ordinary knit fabrics and exhibits exceptional glossiness and color saturation after dyeing and finishing.

II. Performance Advantages and Physical Properties of Tricot Fabric

Tricot fabric exhibits exceptional physical properties, primarily in terms of abrasion resistance, stability, and breathability. Its multi-yarn structure in the warp direction effectively enhances the fabric's tensile strength and durability, allowing it to remain flat and stable even after repeated use and washing.

This fabric also exhibits excellent dimensional recovery, quickly rebounding from deformation under external forces, making it an ideal choice for sportswear and stretch fabrics. Tricot fabric also boasts a smooth surface, a low coefficient of friction, and is resistant to pilling. Its compact structure provides excellent wind resistance and shape retention.

In terms of breathability and moisture absorption, Tricot fabric utilizes microporous structures between yarns to allow air circulation, ensuring the fabric maintains a soft touch and excellent comfort. In modern processes, raw material modification and post-processing coatings are often used to further enhance functional properties such as waterproofing, UV protection, or antibacterial properties, making them more suitable for high-end functional fabrics.

III. Raw Material Selection and Process Innovations for Tricot Fabrics

Tricot fabrics can utilize different raw material combinations depending on the intended use, including polyester, nylon, spandex, and their blends. Polyester tricot boasts excellent strength and color fastness, making it suitable for high-intensity applications; nylon tricot is known for its lightness and smoothness, making it a popular choice for sportswear and underwear. The addition of spandex significantly enhances elasticity and fit, giving the fabric both support and comfort.

With the advancement of textile technology, modern tricot production processes are trending towards high density, multifunctionality, and environmental friendliness. Using CNC warp knitting machines and intelligent tension control systems, the fabric's density, warp-weft ratio, and texture can be precisely controlled, resulting in a delicate weaving texture and diverse appearance. Furthermore, the use of low-temperature dyes and energy-saving processes in the dyeing and finishing stages not only ensures uniform color but also effectively reduces energy consumption and emissions, aligning with the development trend of green textiles.

IV. Key Applications of Tricot Fabric

Tricot fabric plays a vital role in a wide range of sectors due to its stable structure, smooth feel, and diverse functionality. Apparel is its core application. From lightweight underwear and sportswear to functional outerwear, Tricot fabrics deliver exceptional stretch and support, meeting the comfort needs of the human body during exercise. Its excellent fit and durability make it a staple fabric for professional sportswear and high-end fashion brands.

In the home textile sector, Tricot fabrics, with their smooth touch and elegant sheen, are widely used in bedding, curtains, and sofa upholstery, creating a visually delicate sense of layering and high-quality texture.

Tricot fabrics are also experiencing strong growth in automotive interiors, medical protective equipment, and industrial filtration materials. Its stretch resistance, abrasion resistance, and high compatibility make it suitable for lamination, coating, and functional composite processing, opening up new possibilities for industrial applications.

As a representative example of warp knitting technology, Tricot fabric not only embodies the textile industry's precision craftsmanship and innovative potential, but also strikes a balance between functionality and aesthetics. Its unique structural properties support the diverse demands of modern apparel and industrial fabrics. Its lightness, stability, and high elasticity ensure it a key position in the future functional textile market.

With continuous advancements in production technology and environmental awareness, Tricot fabric will continue to play a key role in the global textile industry, becoming a vital link between comfort and high-performance design. For brands pursuing high quality and sustainable development, Tricot Fabric is undoubtedly an ideal choice, combining a technological and fashionable aesthetic.

English

English Español

Español