The manufacturing of 100% polyester fabric has become a cornerstone of the textile industry, offering a versatile and durable material suitable for various applications. Behind the scenes, specialized factories play a pivotal role in the production process, utilizing advanced technology and expertise to bring this synthetic fabric to life. In this article, we delve into the workings of a 100% polyester fabric factory, shedding light on the intricate processes that transform raw materials into the final product.

At the heart of every 100% polyester fabric factory is the processing of raw materials. Polyester is derived from petrochemicals, and the factory begins by obtaining polymer chips, the building blocks of polyester. These chips are then melted and extruded through spinnerets to form continuous filaments. The filaments are solidified, creating a yarn ready for the next stages of production.

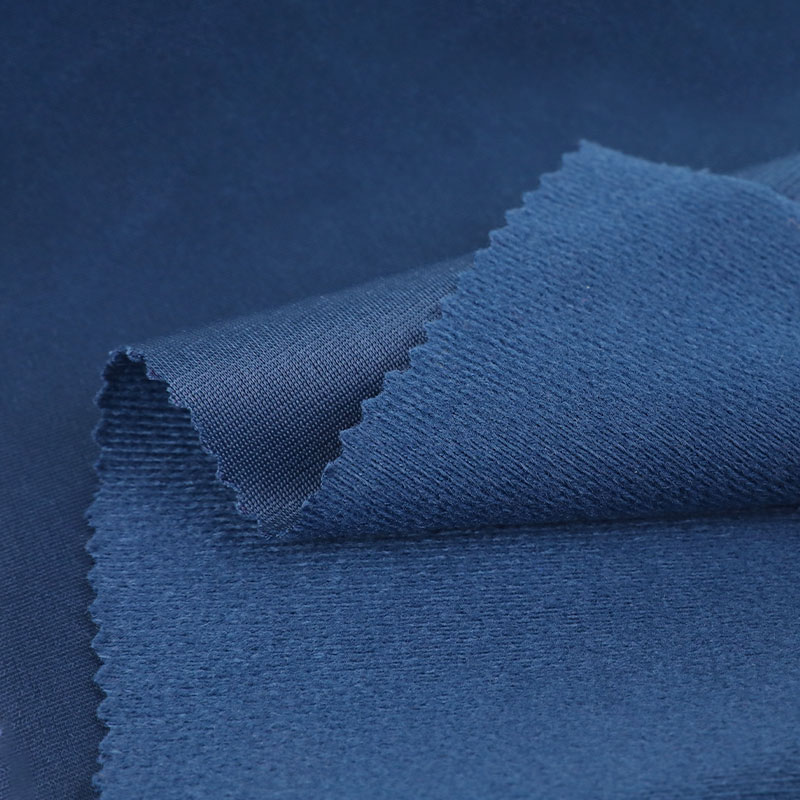

Once the polyester yarn is prepared, it undergoes spinning to create threads suitable for weaving. Weaving, a crucial step in the fabric production process, involves interlacing these threads to form a stable and coherent fabric structure. The weaving process can take different forms, including traditional methods or more advanced techniques such as air-jet weaving, each influencing the fabric's texture and properties.

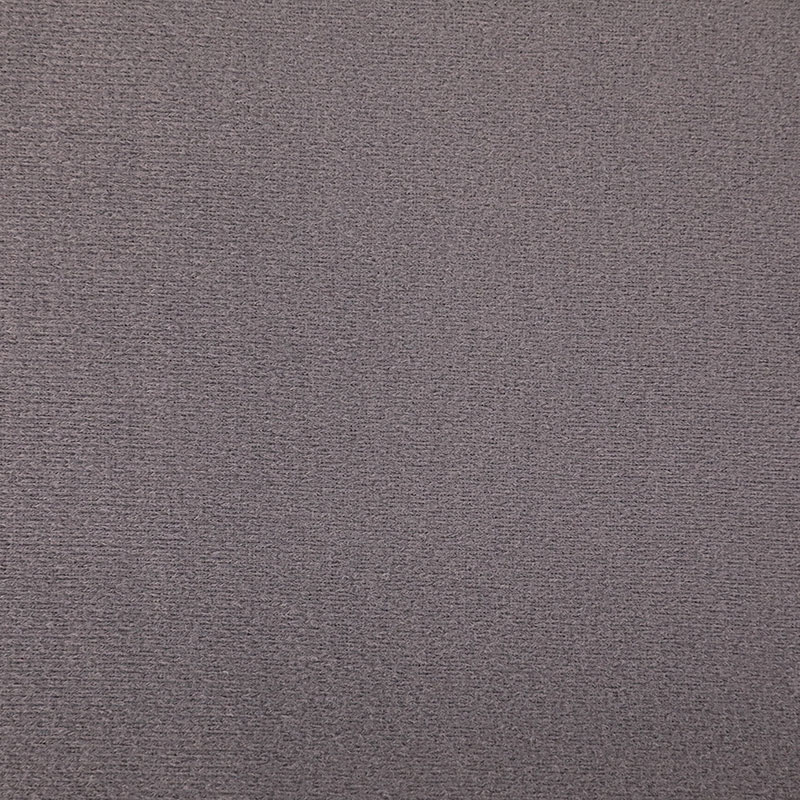

After the weaving process, the fabric is typically in its raw, undyed state. Dyeing is a critical step to impart color and vibrancy to the fabric. Polyester's affinity for various dyes makes it a versatile choice, allowing for a wide range of colors and patterns. Following dyeing, the fabric undergoes finishing processes to enhance its characteristics, such as softening, wrinkle resistance, or water repellency.

Quality control is an integral part of the 100% polyester fabric manufacturing process. Skilled technicians and advanced machinery are employed to inspect the fabric at various stages, ensuring that it meets the desired specifications and standards. This meticulous quality control helps guarantee a final product that is consistent in terms of color, strength, and overall performance.

English

English Español

Español