In modern sportswear, fabric choice directly impacts both the athletic experience and performance. As a new high-performance fabric, brushed sportswear fabric is becoming a core component of the sportswear market due to its unique texture, comfort, and functionality.

Brushed Sportswear Fabric Structure Analysis

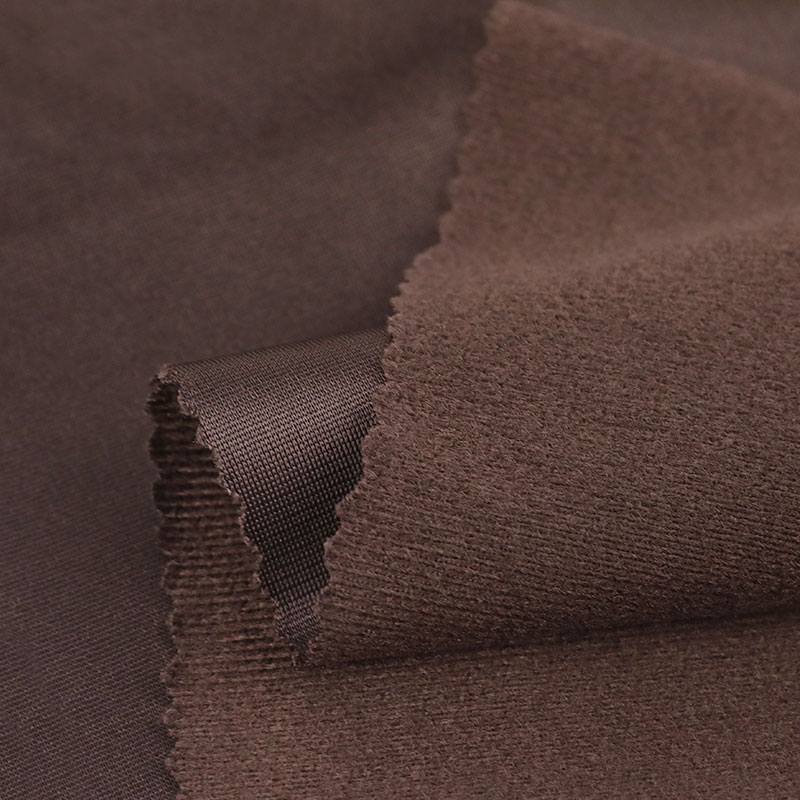

Brushed sportswear fabric is a textile material that achieves a soft surface and a fluffy interior through a special processing method. Its basic structure typically utilizes a double- or single-sided brushing process, creating a microscopic nap on the surface. This not only enhances tactile comfort but also enhances warmth and breathability. The fabric itself is often a composite of highly elastic fibers and natural fibers, such as polyester and cotton, achieving a balance of elastic rebound and moisture wicking and breathability.

Brushed sportswear fabric typically utilizes a knitted structure, which imparts superior stretch and a soft feel, making it suitable for next-to-skin wear while maintaining excellent freedom of movement. Compared to traditional plain or twill fabrics, knitted brushed fabrics are less restrictive during stretch, significantly improving the comfort of athletes at all levels of intensity.

Functional Advantages: A Balance of Comfort, Warmth, and Breathability

The core value of brushed sportswear fabric lies in its multifunctional properties. First, the fleece layer on the fabric's surface effectively traps air, creating a natural thermal barrier that keeps the wearer warm even in low temperatures. Second, the fabric's internal structure quickly wicks away moisture, ensuring sweat evaporates quickly during exercise, keeping the wearer dry.

The fabric's elastic design, combined with the brushed finish, maintains a soft feel during stretch and rebound, reducing discomfort caused by friction during exercise. The comfort and breathability advantages of brushed sportswear fabric are particularly evident during extended training or high-intensity exercise, effectively enhancing the wearing experience and performance.

Manufacturing Process Analysis: Meticulous Control from Fiber to Finished Product

The production process of brushed sportswear fabric embodies the sophistication of modern textile technology. Starting with raw material selection, highly elastic polyester or functional cotton fibers are precision-spun to create highly uniform yarns. Knitting machines then meticulously weave the yarns to ensure consistent thickness, density, and elasticity.

The brushing process is a key step in the manufacturing process. Mechanical or chemical treatment of the fabric surface causes the fibers to curl and stand upright, creating a fuzzy structure. This process not only enhances the fabric's feel but also optimizes its warmth and breathability. Finally, through shaping, dyeing, and finishing, the fabric achieves a soft and smooth surface while maintaining stable functional properties.

Application Trend: Fusion of Sports Fashion and Functionality

With the increasing popularity of active lifestyles, brushed sportswear fabrics are increasingly used in both functional sportswear and everyday athleisure wear. These fabrics not only meet the basic needs of warmth, breathability, and comfort, but also offer a stylish design. Through different fiber blends and surface treatments, brushed sportswear fabrics can exhibit a variety of textures and color variations, meeting the needs of sportswear brands for both fashion and personalization.

In the development of sports equipment upgrades and high-performance sportswear, the innovative applications of brushed sportswear fabrics are expanding. For example, by incorporating functional treatments such as antibacterial and UV protection, fabrics are not only comfortable and warm, but also offer more specialized athletic performance. This trend of multifunctional integration indicates that the future sportswear fabric market is moving towards high-performance, all-round functionalization.

Brushed sportswear fabric, with its unique brushed finish, exceptional comfort, and functionality, is reshaping the sportswear fabric market. From fabric structure and performance characteristics to manufacturing processes and application trends, every aspect reflects the textile industry's pursuit of technological refinement and functional innovation. As demand for high-performance sportswear continues to grow, brushed sportswear fabrics are expected to gain even greater market share in sportswear and related fields, becoming an indispensable core material in the industry.

English

English Español

Español